Mine fires are an unfortunate potential at any operation, but knowledge is power.

A major mine operator recently leveled with a large industry crowd, confessing: “I am scared to death of mine fires. Scared to death.”

Most, understandably, side with the executive on his sentiment. After all, a factor as small as frictional heating — or even a cigarette lighter — can be the breeding ground for a full-blown ignition of a gassy environment to cause a fire or explosion, and even with the ever-growing mine fire suppression and control technology sector there still remains many areas of an operation where a mine fire can develop and thrive in the right conditions.

One of the most high-profile mine fires in recent memory occurred on January 19, 2006, at the Aracoma Alma No. 1 mine in southern West Virginia, when a fire erupted at the mine’s 9 Headgate longwall belt take-up storage unit while a 29-man crew was working underground.

Two of the men, Don Bragg and Ellery Hatfield, perished.

According to a final investigation report released later detailing the incident, initial attempts to extinguish the fire failed, and observations at the scene indicated that smoke from the fire was traveling further into the mine via the 2 Section intake air course.

Miners in affected areas were neither immediately notified nor withdrawn following the initial carbon monoxide alarm signal from the atmospheric monitoring system.

The section crew donned self-contained self-rescuers and began to make their tedious and frightening escape from the mine, holding on to one another and feeling along the coal rib as they moved outby in the dense smoke.

Once out of the smoke, the group discovered that their two crewmates were missing, and smoke and intense heat made rescue attempts by mine management and even mine rescue teams an arduous task.

The bodies of Bragg and Hatfield, who had gotten separated from the group and subsequently lost in their attempt to escape, were located on January 21, about 575 ft apart. The Aracoma fire was extinguished three days after that on January 24.

The U.S. Mine Safety and Health Administration (MSHA) concluded in its probe of the incident that the fire had occurred as a result of frictional heating when the longwall belt became misaligned in the 9 Headgate longwall belt take-up storage unit, and that frictional heating ignited accumulated combustible materials.

“The required fire suppression system was not installed in the area where the fire occurred,” investigators said, noting that the water was turned off to the firefighting waterline in the area, and fire hoses could not be used.

Additionally, the fire extinguishers expended did not extinguish the fire and stoppings that were required to maintain separation between the belt entry, and the primary escapeway for 2 Section had previously been removed.

What sounds like a perfect storm got even more added depth when MSHA revealed that the examinations of the mine were inadequate and failed to identify the lack of separation between the primary escapeway and belt air course.

Additionally, examinations of safety systems failed to identify deficiencies that contributed to the severity and extent of the mine fire, and airflow carried the smoke from the fire to the belt entry and then into the primary escapeway for 2 Section through the openings created by previously removed stoppings.

Aside from what the industry has learned from this and other similar events, what is already known cannot be ignored — mine fires are preventable, and while the industry is working diligently toward the ultimate goal of zero injuries and fatalities, the potential remains for a mine fire to occur again somewhere in the future.

That is where the phrase “knowledge is power” is key. Through education on fire prevention and firefighting techniques, and knowledge of the details of available technology and the resources available to miners across the industry, they can be better equipped to literally fight the fear of fire.

What better place for them to be than in front of the issue?

Firefighting Technologies, Techniques: An Overview

There are nearly as many different ways to fight a mine fire as there are ways for a fire to propagate in the first place. Many investigations of mine fires have focused on determining the cause of the blaze, which has in turn had a significant role in helping to understand what techniques and technologies are the most fundamental and crucial to fight them.

They have also learned from the problems that created past fires, a silver lining in very unfortunate situations.

They know by studying these previous incidents that the problem is not a small one; according to data from MSHA analyzed by the National Fire Protection Association, in the 100-year period from 1900 to 1999, more than 100,000 miners died in all “unintentional-injury causes,” as it has classified them, including mine fires and explosions (this is versus 23,000 miners under that same class in metal/nonmetal mining).

This is in the U.S. only, and equates to an average of 1,040 annually over that time period. In the last decade, that dropped to 45 per year, with about 10% to 15% attributable to fires and explosions at mines per that same data.

Many may credit changing regulations for the improvement in this area over the decades, but a much greater understanding of the mining environment, safety and prevention arguably has played just as much of a role.

The coal mining community has come a long way in its battle against the blaze, and the topic is one of high interest by the research community.

| Table 1: 10 Deadliest U.S. Mining Fires and Explosions | ||

| Location | Date | Number of deaths |

| Monongha, WV | December 6, 1907 | 361 |

| Mather, PA | May 19, 1928 | 273 |

| Dawson, NM | October 22, 1913 | 263 |

| Cherry, IL | November 13, 1909 | 259 |

| Jacobs Creek, PA | December 19, 1907 | 239 |

| Scofield, UT | May 1, 1900 | 200 |

| Coal Creek, TN | May 19, 1902 | 184 |

| Eccles, WV | April 28, 1914 | 181 |

| Chewick, PA | January 25, 1904 | 179 |

| Castle Gate, UT | March 8, 1924 | 171 |

| Source: NFPA major-incident files; U.S. Bureau of Mines, The World Almanac and Book of Facts 1988 and The Great International Disaster Book by James Cornell. | ||

Leading industrial research group, the National Institute for Occupational Safety and Health (NIOSH), including researchers Michael Trevits, Alex Smith and Jurgen Brune, examined the trend in remote fire suppression technology in a past white paper that included inert gas injection, gas-enhanced foam and jet engine exhaust gases into a fire zone.

According to its data findings on mine fires in that research, between 1990 and 2001 more than 975 reportable fires occurred in the U.S. mining industry, or about 81 fires per year on average. Those events caused more than 470 injuries, six fatalities and the temporary closing of several mines.

More than 95 of those fires occurred in underground coal mines, the group said, with the leading causes of mine fires including flame cutting and welding operations, frictional heating and ignitions, electrical shorts, mobile equipment malfunctions, and spontaneous combustion.

On the agency’s radar at that time, just a handful of months past the Sago mine explosion and Aracoma mine fire, were remotely installed ventilation control devices, or mine fire seals, low-flow inert gas injection, gas-enhanced foam, and high-flow rate injection such as jet engine exhaust gases.

Thanks to the work of Trevits and his expert colleagues, citing research done even before them, found significant advances in cement-based remote mine seal construction technology even at that point, as well as the acknowledgment that low-flow inert gas injection technology is best suited for applications where localized mine inertization is desired and is available from bulk tankers and nitrogen plants.

Foam created with nitrogen gas is ideal, NIOSH said, because foam can act as a water reservoir, releasing it at a rate that allows absorption into fuel. The GAG 3A system for high-flow, large volume mine inertization needs was still being examined as use was limited in the U.S.

Fast forward to today, and the foundations of those discoveries and others before them has left the nation’s coal community with high levels of technology available to fight mine fires.

While the spectrum is large, a handful that seem to be popular options come from companies such as Kidde, Pillar Innovations and Phoenix First Response.

Pillar, for example, tied much of its research into the lessons learned from the time period surrounding the Aracoma fire, when federal investigators said that the belt drive fire suppression systems in use were inadequate. Looking to meet both operator needs and regulatory outlines, the company developed the pre-engineered, modular Fire Station system that meets MSHA and NFPA codes. It also has fire suppression alternatives for underground use such as battery charging stations and diesel storage units, generators and mobile vehicle systems.

Suppression and control technology from Kidde is varied, including the DCS suppression system with an ABC dry chemical powder, the LS suppression system that includes the Aquagreen XT aqueous agent useful over a greater temperature range, and the SA1 detection and control system designed to control detection and suppression functions for the Kidde Sentinel vehicle fire suppression system. The Kidde SA1 Control Unit can provide status information and user controls in a compact die-cast aluminum enclosure with multiple available power management options.

Rend Lake College in Ina, Ill., is just one facility that plays host to fire brigade and mien rescue training. (Photo courtesy of Rend Lake College)

At the heart of its line is the Kidde Sentinel NET package, which offers control, annunciation and releasing technologies that provide a flexible array of configuration options such as multiple protected spaces, cross-zoning and even event logging.

In the detection arena, the company has the IR-1 infrared detectors, which operate by sensing two separate bands of infrared energy and generating a fire signal when it sees fire from all types of fuels, lubricants, gases and other combustibles, and the Detect-A-Fire heat detector, which services as an alarm device to sense overheat and trigger alarms or as a release device to sense fire and actuate the suppression system.

On the service side in this sector is Phoenix First Response, which is a one-stop-shop of sorts for assistance ranging from gas analysis and mobile emergency serves to sampling and testing for the ever-changing regulations of the U.S. Environmental Protection Agency (EPA). The company also has comprehensive emergency management, consultant and investigation services and can provide seals, stoppings, surface-to-underground plugs, and downhole drilling and cameras.

It utilizes IGS Generon for nitrogen generation services, and its fire suppression consulting and products line-up includes ThermoGel, ThermoFoam, ACAF systems and ColdFire.

Mine Rescue Teams vs. Fire Brigades: A Disconnect?

In late 2013, MSHA issued a notice in the Federal Register to inform the mining community of a sizeable change to its outlines — the scheduled amendment and re-release of certification criteria for mine rescue teams under the Mine Improvement and New Emergency Response Act (MINER Act) of 2006.

In it, the agency revised its instruction guides for annual training requirements of coal mine rescue teams including Section 49.18(b)(4), which requires advanced mine rescue training and procedures in Advanced Mine Rescue Training — Coal Mines, or IG7, and added to it Guide IG7a, containing new practical exercises.

The materials for classroom training are retained as Instruction Guide IG7, Advanced Mine Rescue Training — Coal Mines and the practice exercises are moved to new Instruction Guide IG7a, Advanced Skills Training — Activities for Coal Mine Rescue Teams.

Instruction Guide IG7a also contains new exercises to assure practice on skills a team would need in a mine emergency, as well as expectations training.

After a comment period that closed in late November 2013, during which MSHA received five comments from across the industry, the agency published the new information in the Federal Register and on its website.

One of those comments was important to this discussion but largely ignored: an unnamed commenter stated that teams would be better trained if the training consisted of actually putting out a fire, being exposed to heat and dense smoke, and spending more time preparing for an actual emergency.

In response, MSHA said it believes the exercises prescribed in IG7a will provide appropriate training in smoke, fire hose management and firefighting. Period.

Another commenter said that IG7a should be revised to include a smoke tube exercise. That input was heard, with MSHA revising IG7a to include a smoke tube exercise in which tubes filled with a visible chemical smoke are opened and the escaping smoke is carried away by any air flow.

“In the agency’s experience, smoke tube training will help prepare teams to determine the ventilation direction and measure speed in areas with low air velocity, which may be encountered in a mine emergency,” officials said.

It is well known that the regulatory rules for mine rescue teams, particularly post-MINER Act, are fairly articulate and detailed, including distance limits for teams from mines and the number of competitions any one team must participate in during a given year.

However, the skills of a mine rescue team and those of a fire brigade team have a broad gap. There is still a significant disconnect between requirements for mine rescue crews and those who train on firefighting techniques. Many mining companies and crews opt to polish their skills in this area largely on their own — perhaps to ensure complete comprehensive training for any emergency, or perhaps even out of that aforementioned fear. How long until these two important pieces of miner safety are viewed equally?

Combating Fires with Training, Education

The fire brigades that do exist in the mining community must have a place to learn and train, and thankfully there are options for those crews. One of them is the Kentucky Coal Academy’s Mine Emergency Response Academy (MERA) in western Kentucky.

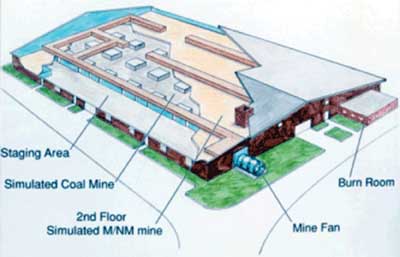

A cross-section of the training facilities at the National Mine Health and Safety Academy in Beaver, W. Va. (Image courtesy of MSHA)

Madisonville Community College, using the former Madisonville Community College technology campus, opened MERA in March 2011. It features a simulated mine offering an almost-real environment to the underground coal mine as well as a Class A burn room that can also be utilized for structure fire education.

The spotlight feature for fire brigades is the burn prop located inside the simulated operations, which school officials say closely incorporates the key tools and skills to fight and extinguish an actual mine fire.

“One of the greatest components of a fire in an underground mine fire is to redirect the ventilating current to make control of heat and gasses generated. Our simulated mine, because of its concrete structure, is designed to facilitate this skill,” Kentucky Coal Academy fire brigade instructor Rick Caskey said, noting that the facility has been designed to attract crews from the Illinois Basin and beyond.

MERA is funded through the Kentucky Coal Academy in partnership with the West Kentucky Workforce Investment Board and, in addition to mine rescue and command center training, offers a 16-hour instruction program for inexperienced fire brigade training as well as an eight-hour course for experienced teams and individuals.

Just a few hours northwest of Madisonville in Ina, Ill., is the Rend Lake College Coal Mine Training Center, which includes a specific training center for both mine rescue and mine fires. The center opened in 2009, and the specialized training portion had its grand opening the following year.

The 20,000-sq-ft center in southern Illinois was awarded about $2.7 million in federal and state aid for its design, engineering and construction, and also to provide equipment for teams to use such as a mock mine and faux smoke for rescue drills.

The school’s mining technology department has been bestowed Brookwood-Sago grant funds from MSHA on more than one occasion, and the most recent earmark is being used for an expansion at the firefighting facility.

“The grant will be dual use, for both our coal mine students and civilian firefighters,” dean Chris Nielsen said. “We get to use the local firefighters as our instructors, so our students learn from the best.”

An interesting aspect of RLC’s mining program is that it was revamped in 2009 after a long history of success. At one point in the late 1970s and early 1980s, hundreds of students and 17 mining instructors were in the classroom around the clock, three shifts a day and seven days a week. It even boasted a 97% placement rate for those graduating the program. A strong of mine closures in the 1990s, tied largely to Clean Air Act amendments, left the market for inexperienced workers dry and the facility much less in demand.

Today, however, from fire training to new and refresher operations courses, RLC is one again bustling with activity. Even with the industry’s challenging times, the Illinois Basin is enjoying healthy growth and those with certifications and associate’s degrees are ready for any open spots in the region.

“What this center does is centralize training for the coal mining industry,” school president Charley Holstein said when the facility opened in 2009.

He foreshadowed the success of the programs when he promised the “regional approach” it would create to training in the coal industry in particular.

“Industry, the college and the state agree this is the perfect central location, and with our history and record in coal mining training, we’re excited about the potential here,” Holstein said.

One of the larger fire training programs for existing and potential brigade members is at West Virginia University. The WVU Mining Extension simulated underground mine lab at Dolls Run in Core, northern West Virginia, came online in October 2009, and today offers one of the most realistic mine fire experiences available nationwide.

In addition to the full-facet ventilation features at the facility, crews can experience the heat and intensity of a live fire at the mine’s burn area and see the inside environment of an actual refuge chamber.

Mobile training units at the simulated mine are equipped with a changeable smoke maze, or confidence maze, for SCBA practice as well as SCSR expectations training drills.

Hands-on extinguisher and hose experience training using remotely controlled fire plans is another feature of the MTUs.

WVU’s simulated mine also has a working 4-in. water line along a conveyor belt, powered by surface sources and complete with fire taps and shut-off valves for use in the smoky, alarming environment that a mine can transform into during an actual mine fire event.

Training is conducted at the WVU Dolls Run facility by a staff from the school’s mining extension division; other instructors include fire experts working out of the National Mine Health and Safety Academy in southern West Virginia.

Dolls Run often plays host to industry competitions; last September it welcomed six teams from Murray Energy for the producer’s annual fire brigade competition that included contests of self-contained breathing apparatus examinations, a search-and-find mapping and navigation exercise, a physical challenge that involved firefighting gear and SCBA donning to push, drag and carry fire rescue equipment and dummies over a set distance for time, a live interior firefighting exercise in the simulated mine, and an air management obstacle course.

“Uncontrolled mine fires have yielded many fatalities over the years, and they will ultimately close an operation,” mining extension agent Josh Caldwell said last fall. “Although fire brigades are above and beyond what the law requires by way of fire protection training, mine operators like Murray Energy realize the benefit to investing time and resources into training these specialized groups. They have proven beneficial by extinguishing fires at Murray operations in the past, thus saving the operation, workers’ lives, their wages and benefits.”

It is hard not to notice that, while mine rescue facilities exist in the western coalfields, those with a focus on mine fires and fire brigade training are lacking in that region as most are based east of the Mississippi.

Teams and individuals, regardless of location, do have another option — the MSHA Academy in Beaver, about 90 minutes from Charleston, which offers training to miners as well as its own federal inspectors on a myriad of skills.

The 48,000-sq-ft facility on one end of the 80-acre academy grounds houses a simulated coal mine on the bottom level (designed as a four-entry room and pillar mine with four crosscuts) and a simulated metal/non-metal operation on the second floor. One end of the coal mine portion includes the burn room where officials set controlled fires to teach firefighting skills as well as emergency ventilation.

A 100,000 cubic-ft-per-minute solid-state electronics-controlled mine fan can vary air volumes delivered throughout the entries and crosscuts in both simulated mines.

Students are given simulated exercises that provide near actual mine emergency and firefighting experience unavailable anywhere else in the world, according to facility officials. After participating in the simulation training, students leave the academy with a better idea of how to handle and perform in an actual mine emergency situation.

WVU, which offers students skill building on temporary and permanent ventilation control construction while under apparatus as well as how to measure dangerous gases, also has an outdoor firefighting area for drills that also has a controlled gas feed.

Finding a Future in Fire

Could the mine fires of yesterday play a role in saving lives tomorrow? Moreover, could the next new drug to fight cancer come from the deep mines of Kentucky? Possibly, according to one of the state’s major universities.

Last November, researchers at the University of Kentucky’s Center for Pharmaceutical Research and Innovation (CPRI) said that, as part of an ongoing quest to develop the latest and most effective drugs for disease treatment, it was looking deep underground for answers to this very question.

Under a new UK-based bioprospecting initiative involving a collaboration between CPRI, the Center for Applied Energy Research (CAER) and the Kentucky Geological Survey (KGS), the groups are collecting samples from unusual environments throughout the commonwealth of Kentucky with the goal of finding new and unique organisms that produce natural products that could potentially be used to develop new drugs with an initial focus on treatments for cancer, infectious disease and inflammation.

According to UK, many existing effective drugs are made by microbes; the antibiotic erythromycin, for example, is a natural product formed by bacteria found in soil.

The anticancer agent doxorubicin is also a microbial-produced natural product.

CPRI Director Jon Thorson and an 11-member lab team said late last year that they had joined a large consortium of investigators at the school who are all focused on the discovery and development of natural product-based drug leads from unique sources including bacteria, fungi and plants.

Thorson also serves as the co-director of the Markey Cancer Center’s Drug Discovery, Delivery and Translational Therapeutics Program and co-director of the Drug Discovery and Development Core in the UK Center for Clinical and Translational Science.

“The University of Kentucky is a remarkably rich and highly collaborative community for natural products-based research. As part of this effort, we are looking for new microbes that can product novel bioactive molecules,” Thorson said.

“Instead of looking in places where other people have already been, we’re trying to access new frontiers. The collaboration with CAER and KGS allows us to sample unexplored environments in the context of natural products discovery.”

The most recent “new frontier” that Thorson’s lab is exploring has very deep roots in the commonwealth, both literally and figuratively.

How do those past fires play a role? Well, through the collaborations with CAER and KGS, Thorson said the team has an opportunity to study products taken from Kentucky underground and surface coal mines, including thermal vents from underground coal mine fires, mining reclamation sites and deep-well core drilling operations for carbon sequestration.

The initial collaboration with CAER involved studying emissions, and the corresponding microbes, associated with underground coal fires. The heat of the fires combines with the varying flora and mineral makeup of each site to create a distinctive environment for sampling.

“We decided that the coal fire sites were a very good starting point, because they are fairly unique,” CAER principal research scientist Jim Hower said. “They’re really a prime target for sampling.”

CAER has further helped drive the success of this project by introducing CPRI to new contacts in the commonwealth, Thorson added. Hower and Greg Copley of CAER introduced CPRI to additional collaborators within the CAER as well as leaders of U.S. Coal subsidiary Licking River Resources and the Kentucky Division of Abandoned Mine Lands, both of which have facilitated CPRI access to additional unique collection sites.

Through KGS’ core drilling operation, Thorson’s team has also accessed samples from deep underground; in fact, during drilling in the eastern Kentucky coalfield earlier this year, more than 40 samples of drill cuttings from depths ranging from 100 ft to nearly one mile underground were collected and sent to Thorson’s lab. Drill cuttings are ground rock that are continuously pumped out of a well during the drilling process.

“Once you drill below about 2,000 ft, the salt concentrations in the water found in pores in the rocks are about three to five times that of the ocean,” KGS research geologist Rick Bowersox said. “As might be expected in a subsurface environment, the microbes are very different from those in a typical surface soil environment. These microbes have adapted to an environment of extremes in water chemistry, pressure and temperature.”

While barely a year old, Thorson’s program has already deposited more than 75 compounds in the new UK natural products repository — all from microbes found in Kentucky.

Could Kentucky’s natural landscape potentially yield the next big cancer drug? Thorson said he has high hopes.

“Natural products have been and continue to be a driving force in drug discovery,” he said. “And the hope is that some of tomorrow’s therapies may come from the coal mines here in the commonwealth.”