DESPITE THE TIMES, OLD AND NEW NAMES ACQUIRE ASSETS AND BEGIN TO CHART A NEW COURSE

By Donna Schmidt, Field Editor

| The Hampden mining complex was sold by James River Coal to Blackhawk Mining’s JR Acquisition last August. (Photo courtesy of James River Coal) |

It goes without saying that the mining community is still waiting for the coal markets to regain steam and return to the place where mines were hiring, engineers were designing new projects, and suppliers were, well, supplying. There is still much of that happening, but at a more tempered rate and with much more caution by all involved until a true and confirmed recovery can be seen.

It has also been widely reported, in large part by the public media, that Appalachia has been hit hard by the rough tides of the coal market. If one believes the 6 p.m. news, coal is at the cliff, hanging on by fingernails, with the aggressive hand of the Environmental Protection Agency (EPA) the only thing standing between life and certain death. The thousands of miners who once held jobs are, as they describe it, long gone from the coal communities, leaving behind desolate towns and empty, crumbling coal portals.

While it is true that Appalachia has seen more than its fair share of hard times as of late, at least in relative terms to its coal-mining counterparts in the western and interior states, investments are being made in the mining-rich mountains. Some see the market as an opportunity to gain a larger footprint in a region that is far from singing its swan song. There is also an active political scene, particularly in West Virginia, that is sure to tie tightly into coal’s future, and many fierce and staunch supporters of coal in the Appalachian region are far from giving up.

For example, many raised eyebrows at the announcement last year that the bankrupt James River Coal would divest its interests. What would become of the mines? Would they wither and fail in the wake of their owner’s legal case? Who would buy them in a depressed market?

Turns out there was, in fact, interest in those assets, and over the coming months they were acquired. While JRC did take a loss, it divested its Hampden, Hazard and Triad complexes (note: these mines are in Central Appalachia (CAPP) as well as the Illinois Basin (ILB) region to Blackhawk Mining’s JR Acquisition in a $53 million deal last August.

The purchase of Hampden also included the assets of Logan and Kanawha Coal Co., but the purchase of Hazard did not include Laurel Mountain Resources.

|

| The Bell and Bledsoe mining complexes were acquired by privately held Revelation Energy in early 2015. (Photo courtesy of James River Coal) |

Fast-forward to February, when JRC confirmed it had sold the last of its mines in CAPP — the Bell and Bledsoe thermal complexes, as well as previously unsold assets of the Laurel Mountain Resources subsidiary. The $2 million transaction was made with privately held Revelation Energy, owned by West Virginia philanthropist and energy asset holder Jeff Hoops.

Neither company has publicly commented on their plans for the former James River mines, but their fate is significantly better than remaining in limbo between production and mothballing.

Additionally, on February 17, coal magnate Jim Justice announced that he bought back his Bluestone assets first sold to Russian miner Mechel OAO in 2009, which includes operations in McDowell and Wyoming counties, West Virginia, and will open the doors on a brand new company, Bluestone Resources.

|

| Coal magnate Jim Justice announced in February that he bought back his Bluestone assets first sold to Russian miner Mechel OAO in 2009; he will now open the doors on a brand new company, Bluestone Resources. (Photo courtesy of Mechel) |

Mechel, then the largest steelmaking coal producer in Russia, initially paid $436 million in cash and 83.3 million of its preferred shares for the group in May 2009. What the miner will now get back from the Justice family includes an immediate cash payment of $5 million, royalty payments on coal mined and sold in an amount of $3/ton, and a portion of any future sale of the company and/or its assets of 12.5% of the sale price if within five years of transaction close or 10% of the sale price after year five, but before year 10.

Now troubled, Mechel closed the deal with the newly monikered Bluestone Resources and the two parties have agreed to terminate all claims against each other, including their unresolved dispute related to the calculation of a contingent payment obligation arising out of the first 2009 transaction.

“With the market situation being what it is, mining at Mechel Bluestone’s mines and open pits is not profitable,” said Oleg Korzhov, CEO of Mechel, last month, noting that the company’s average annual net loss since 2012 was around $60 million.

Selling the Mechel Bluestone arm will enable it to avoid continued losses and also to remove $140 million in liabilities from its balance sheet. It also erases around $160 million in legal risks.

In his announcement, Justice told the media that his new company will create an estimated 150 jobs within the first three months while also continuing to grow going forward.

“You cannot tell the story of the United States without including coal, and West Virginia coal has been the engine for our nation for more than 100 years,” he said. “[This] announcement shows that the coal industry and more than 150 West Virginia coal miners in the near term will be going back to work producing coal to make the highest quality steel for our nation and the world as well.”

A GAUGE OF PROGRESS: THE WVCA

In the country’s second-largest coal producing state, and the top home to underground coal mines across the U.S., there is one coal advocacy group that boasts both a massive following and the ability to effect policy: the West Virginia Coal Association (WVCA). The group’s annual meeting in late January attracted hundreds from both inside and outside the “Wild and Wonderful” state and also served, as it always does, as an indicator of where Appalachian coal is and where it is going.

|

| The West Virginia Coal Association symposium included a panel of speakers on new federal proximity regulations,including MSHA’s Patricia Silvey and other agency representatives. |

With a diverse schedule that included updates on legislation, environmental issues, mine safety progress and more, the symposium — which outgrew its meeting venue a few years ago and is now held at the Charleston Civic Center — consistently proves that it has its finger firmly on the pulse of Appalachian mining.

Much like its neighboring states of Kentucky, Virginia and Pennsylvania, West Virginia did see losses last year to its total mining payroll. According to Office of Miners’ Health, Safety and Training data, however, there were still 47,490 total employees at the state’s mines; 103 of West Virginia’s 214 open underground mines produced coal, and 100 of the 212 surface mines produced during the calendar year.

The well-attended event also drew a national spotlight, which was also an arterial topic when Mine Safety and Health Administration (MSHA) Assistant Secretary Joseph Main took the stage. In his remarks, he focused much of his energy on U.S. initiatives where West Virginia is leading the way, including changing the mine safety culture in a positive way as well as improving respirable dust and the upcoming changes with federal rules on proximity detection.

Main reported that the agency has seen a reduction in respirable dust levels since 2009; yearly average levels for designated mining occupations in underground coal mines, using data from mine operator samples, dropped to an historic low level in 2014 of 0.67 milligrams per cubic meter of air (m/mg3), down from 0.77 m/mg3 in 2009. Also, the yearly average of respirable dust levels of designated mining occupations in samples collected by MSHA inspectors in 2014 dropped to an average of 0.70 m/mg3, compared to 0.83m/mg3 in 2009, which is another new low.

MSHA also recently compiled the results since Phase 1 of its respirable dust rule went into effect (last August 1-December 31), and found extremely high compliance with the new standards: 99% of the 23,600 valid samples met compliance levels.

The state of West Virginia was also ahead of the federal government on its implementation of outlines for proximity detection systems. (For more information on the incoming federal regulations and phase-in dates, see page 17.) A proximity panel held at the event detailed the highlights of the final rule, requirements for system checks, what sections of the rule go into place in 2015 and other key deadline dates.

“Credit goes to members of the mining industry for their efforts to improve mine safety and health by designing better dust control systems, leading the way on proximity detection technology, and complying with new safety and health regulations and other actions,” he said.

Gov. Earl Ray Tomblin perhaps summed it up best during his State of the State presentation held during WVCA 2015 before a packed house of attendees: “We must…support existing workers, especially our state’s hardworking coal miners. I know times are tough, but let me be clear, I will never stop fighting against federal regulations that harm our state’s energy industry and devastate our miners, their families and our communities.”

He noted that, in December, the state filed comments related to the Environmental Protection Agency’s (EPA) carbon pollution emission guidelines and urged it to reconsider its proposed plan.

“Federal bureaucrats must understand the impact these new rules will have on families and communities here and across the country [and]…we must work together to develop reasonable, achievable goals that balance the environmental protection we all support with the economic growth we must maintain.”

|

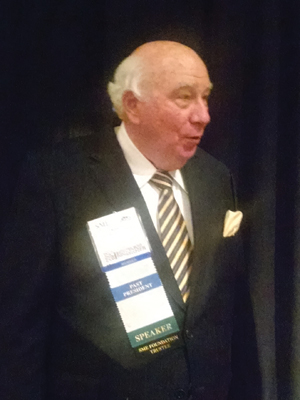

| Murray Energy President Robert E. Murray now owns more assets in the Appalachian region than any other operator. |

APPALACHIAN COAL GOES WEST

One of the region’s largest coal mine operators, at least since 2014, is Murray Energy Corp. Its owner, Robert Murray, is never one to mince words — particularly when it comes to his Appalachian-based operations and the state of the industry at the hands of the Obama Administration. He recently stood up for his portfolio, which makes up a sizable percentage of the region’s currently active operations list, during a keynote speech at the Society for Mining, Metallurgy and Exploration’s Coal Division luncheon in Denver.

While some, he said, may or may not make it through the cyclical downturn, and yet others will tread through on careful footing, he has confidence that his mines will survive “the regulatory onslaught of the…administration as well as any coal company of which we have knowledge,” and one would have a hard time arguing that his persistence and drive mirrors much of the attitude of Appalachia as a whole: a region that has been through many ups and downs, but that always comes through in force.

Murray attributed his survival path to his “concentric ellipse” strategy developed in the late 1980’s to comply with the 1970 amendments to the Clean Air Act, was amended again in 1990.

“Today, the same ‘concentric ellipse’ strategy will make our companies, to a great extent, immune to the destruction of the United State coal industry by President Barack Obama and his appointed bureaucrats and elected supporters. Through this…strategy, our mines serve base-loaded electric power stations that were scrubbed 17 years after development of my strategy. It will be impossible to obtain a reliable natural gas supply or adequate pipeline capacity to those plants; also we are connected to these plants primarily by barge/truck and water transportation, which is at a much lower cost than that by railroad.”

He also cited possessing “the highest value coal seams, with generally excellent mining conditions,” and pointed out that he utilizes 13 very productive longwall mining units and 46 continuous miner sections.

“On top of this, we manufacture virtually all of our own equipment at four factories, employ 11 state-of-the-art large coal preparation plants and operate our own fleet of 23 towboats and about 600 barges. This will all help us survive the current industry challenge.”