The GMSG noted that state-of-the-art technology developments have been driving mining-equipment productivity improvements forward at a steady pace, but a lack of integration has left operators faced with a confusing labyrinth of proprietary systems and multiple display devices. One example is on large shovels, today loaded with numerous independent operator interfaces and screens in the cab, posing potential safety risks such as lessened visibility, complacency or inadequate response behavior, and insufficient situational awareness due to data and information overload. Operator efficiency and productivity are negatively affected as operations wrestle with the task of turning a vast amount of real-time equipment and production data into supportive operating information. This myriad of instruments, said the GMSG, needs to be orchestrated into an integrated interface designed to ensure the right information is available to the operator at the right time.

Although technological advances have resulted in rapid development of performance monitoring systems, a lack of integration among these products has left mining shovel and other large-equipment operators facing a confusing conglomerate of proprietary systems and multiple display devices.

In response, the organization is developing a unified operator interface that will pull together the many divergent systems seen today on large shovels. Work began in 2012 by SA Technologies, through site visits to Teck’s Highland Valley copper mine in British Columbia, and Barrick Gold’s Goldstrike complex in Nevada. On-site interviews and onboard observations with 14 shovel operators fed the design of a unified operator interface that was made public by the end of the year.

“The overall goal is to mitigate against the proliferation of displays in equipment cabs. This phenomenon leads to a low level of situational awareness for the operator, and can have a wide range of negative impacts from safety to productivity,” said Andrew Chapman, production systems engineer, Barrick Gold and GMSG leader on this project. “We have focused our efforts on porting multiple independent data streams to a unified display while prioritizing the available alarms and information.”

This spring, Peck Tech Consulting was engaged to develop a working proof of concept (POC) software implementation of a Unified Shovel Interface, which integrates multiple vendors’ systems into a single interface using only one or two displays. They are working toward a standard Application Programming Interface (API) for connecting onboard devices, and will produce a practical working example of a Unified Shovel Interface.

According to Sandy Pyke, director of technical services at Peck Tech Consulting, this project is poised to enter the industry at a crucial time, and carries the potential to shift the operational landscape by addressing the divisive nature of existing operator interfaces and technologies. “This project is important because it will define a means for systems built by different suppliers to work together on one integrated display,” Pyke said. “These suppliers are often competitors and achieving cooperation between them is difficult if not impossible without the definition of some form of standard.”

The project addresses some potential barriers from stakeholders, which is why it is being developed and rolled out in multiple phases and generations. “The first phase is aimed at allowing these systems to share a common screen with little to no involvement from the system supplier,” Pyke said.

“The second phase grows from this and allows those suppliers to send information to the display to communicate some information. The interface will be simple to implement and the benefit to them will be that they are now able to request that their application take the focus based on a prioritization scheme. Everyone will want their system to be in focus of course, so a prioritization scheme will be defined as well,”

he said.

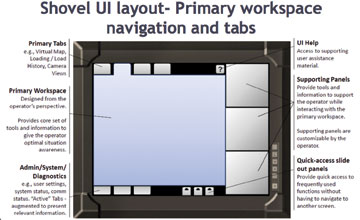

A preliminary screen layout arrangement for a Unified Shovel User Interface.

A preliminary screen layout arrangement for a Unified Shovel User Interface.

“The last phase of the third generation is to support shared services from the display such as GPS location information, engine parameters, sensor parameters and the like. This would allow simpler application development and minimize the amount of hardware that each supplier needs to provide to make their application work,” he said.

They currently intend to demonstrate phase one of the first generation in August, and are hopeful that the next phase will follow in quick succession because of an encouraging response from equipment vendors, Pyke added.

Chapman said the nature of the GMSG, based on industry-wide collaboration, is enabling this project to advance quickly.

“Perhaps the most significant challenge associated with this initiative is the proprietary nature of the technology vendors—this is a fiercely competitive market,” said Chapman. “Despite this fact, our working group has attracted an impressive list of OTM (technology manufacturers), OEM (equipment manufacturers), consultants and mine operators, and grows with each passing week. I am continuously surprised and impressed with the willingness of companies to collaborate with the group—not only does this lend credibility to our endeavors, but also speaks volumes about a new and exciting culture change within the mining industry with respect to collaborative innovation.”

The functioning, “manipulatable” Unified Shovel Interface proof of concept was scheduled to be unveiled during a joint workshop between the GMSG and the Earth Moving Equipment Safety Round Table (EMESRT), on August 15 in Montreal, in conjunction with the World Mining Congress and the International Symposium on Automation and Robotics for Construction and Mining.