More than 52,000 people visited the Las Vegas Convention Center for MINExpo 2012.

Billed as the largest gathering of mining professionals and equipment suppliers, MINExpo International 2016 is scheduled to take place September 26-28 at the Las Vegas Convention Center. Organized by the National Mining Association (NMA) every four years, the event gives the professionals involved in mining and mineral processing a chance to see the latest equipment, listen to presentations and meet with their peers.

So, what can delegates expect at MINExpo 2016? Coal Age asked the NMA and several of the leading equipment suppliers that question. The association is building on its prior successes with some interesting twists. Some vendors are keeping their MINExpo 2016 activities under wraps, but a few did share their plans.

As a point of reference, MINExpo 2012 set new records as far as the number of exhibitors (1,865), exhibition space (860,000 ft2) and attendance (52,000). That, however, was a different time, when business for both coal and metal mining companies was brisk. In the ensuing four years, the coal industry has suffered a rout. Prices for metals weakened and some have since recovered, but not to 2012 levels.

Organizing an event of this magnitude is no easy task. With the help of others, Moya Phelleps, senior vice president, member services for the NMA, manages MINExpo. Describing what delegates would see at this year’s event, she said many of the exhibitors are bringing large equipment and unveiling new models. “Participating in MINExpo is a huge financial commitment and they not only want to support the mining business, but they believe strongly that the mining industry has a bright future,” Phelleps said. “In 2012, MINExpo hit all of the high points. The last 18 months to two years, however, have been particularly challenging for both sectors, coal and hard rock mine operators. The number of exhibitors is about the same as this time four years ago, and so are preregistration levels for delegates.”

Phelleps said visitors can expect to see new technologies and services that can lower production costs, improve productivity and improve safety. Technical experts will be available to assist operators with daily issues and challenges.

Visitors will also notice some differences. As many as 25% of the exhibitors are new companies. There will be several international pavilions on the show floor, including Canada, China, Australia, Chile, Germany, France and Sweden. “France and Sweden are new this year,” Phelleps said. At this point, 840,000 ft2 at the Las Vegas Convention Center has been booked, which is all of the indoor space, but Phelleps said they do have limited outdoor space available.

Acknowledging that times are difficult, the NMA has been working with its producer members to get as many people from the mines to the show floor as they can. At its annual fall board meeting in 2015, the NMA decided to waive the registration fees for all miners whose companies are members of the NMA. “All of our producer members and those member developing properties in the U.S. — Cloud Peak Energy, North American Coal, etc. — will have company-wide complimentary registrations no matter where they reside,” Phelleps said. “This is a big commitment on our part. It was well received by the producers. All of the producers have agreed to bring large contingents of personnel to [the] show and some are planning to host company meetings at the event. The vendors have committed to bringing their customers to the show as well.” This is a $100 savings before the August 12 deadline, and $200 afterward.

The Largest Mining Exhibition

The chairman of MINExpo 2016 is Denise Johnson, president of Caterpillar’s mining division. This is the first time the event has been chaired by a woman. She and other dignitaries will cut the ribbon at an opening ceremony on Monday morning, September 26. Afterward, the crowd is invited to attend an opening session from 10 a.m. to 11:30 a.m. “We are building on the success of the opening session we hosted in 2012,” Phelleps said. “That was the first. This time we have Nina Easton, chair of Fortune’s Most Powerful Women International and a Fox News analyst, moderating a panel discussion with senior mining industry executives discussing the issues of the day and the future as they see it.”

While it is understood that MINExpo is more of an equipment exhibition, the event does have a technical program with presentations from professionals on various topics related to mining and mineral processing.

“We have organized 20 sessions covering a number of topics: safety, markets, research, equipment maintenance, water, surface mining, underground mining, automation, exploration, bulk materials, processing, etc.,” Phelleps said. “These discussions will take place on the mornings of September 27 and 28.”

As it has in the past, the NMA will also host two awards luncheons: the Sentinels of Safety (Tuesday, September 27) and the Department of the Interior’s Sustainable Development and Reclamation Awards (Wednesday, September 28). Hecla is sponsoring the Sentinels of Safety. “A silver miner celebrating its 125th anniversary, Hecla is also a signatory to NMA’s CORESafety program,” Phelleps said. “On Wednesday, the Office of Surface Mining will present coal operators with reclamation awards. The Bureau of Land Management will recognize metal-nonmetal miners with sustainable development and reclamation awards.”

The NMA is also expecting strong international participation. “In 2012, about 35% of the attendees came from abroad and we expect that number to be about the same,” Phelleps said. “We have formed 30 delegations, building on the 20 delegations that participated in 2012.” The foreign delegations this year include Algeria, Australia, Bolivia, Brazil, Canada, Chile, Colombia, Cote d’Ivoire, Czech Republic, DRC, Ecuador, Ghana, Guatemala, Guinea, India, Indonesia, Jordan, Kazakhstan, Mexico, Mongolia, Nigeria, Peru, Philippines, Poland, Romania, Russia, Saudi Arabia, Tanzania, Turkey and Ukraine.

These delegations are part of the International Buyers Program organized by the U.S. Department of Commerce (DOC). The DOC Commercial Services’ division selects a limited number of exhibitions and they work with the embassies to bring qualified buyers to the exhibition. These qualified buyers want to conduct business with U.S. companies. “With the delegations, we offer them an opportunity to present market briefings,” Phelleps said. “People who want to learn about these foreign markets can speak directly with knowledgeable people who know them best.”

As the excitement builds toward the event, the NMA plans to keep everyone informed by whatever means necessary. At MINExpo 2012, the association used social media well. It has evolved, and they plan to take full advantage of this medium to communicate with delegates. “We will have a large social media presence and that will continue to grow toward the show,” Phelleps said. “We have not changed the ways we promote MINExpo, but we have added the social media aspect. The momentum will start to grow in August as companies begin to bring the equipment to the convention center.” To stay informed, delegates should register and follow MINExpo on Twitter, Facebook and Instagram.

Similar to 2012, there will be a MINExpo app for smartphones to assist with planning prior to arrival and navigating the floor on-site. The association will also publish an online directory, which will remain on the website (www.minexpo.com) for a year after the event. There will also be an Export Interest Directory associated with the International Buyers Program. As of press time, more than 1,800 companies were planning to exhibit at MINExpo 2016. What follows is a small sampling of what some of them have planned for the event.

Joy Global Shows Miners How to Do More With Less

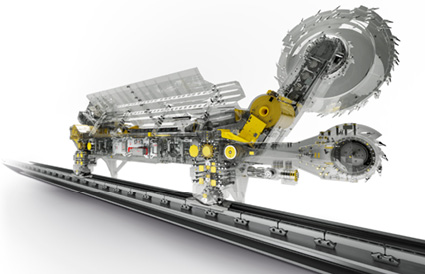

With a focus on helping its customers do more with less, Joy Global (Booth 6211) will highlight new products and services designed to lower customers’ total cost of operation and remove people from harm’s way. Products featured will include a new surface drill, underground hard rock loaders and industry-leading attachments from Montabert. Technology on display will include Joy’s SR Hybrid Drive, which allows power generation that is fully regenerative, resulting in efficient machine operation across several of Joy Global’s product lines. A key feature of the company’s new underground loader series, SR Hybrid Drive is also featured in its new P&H 2650 hybrid excavator, which will be highlighted at the show. JoySmart Solutions experts will also be on hand to discuss how the company’s integrated offerings can help customers reduce costs and increase productivity.

In the four years since the last MINExpo, Joy Global has developed new technology for surface and underground mining.

Hitachi Introduces Integrated Solutions

Visitors calling on Hitachi (Booth 8527) will discover the value of the products, technology, parts, and solutions that have been engineered and developed exclusively by the company. The “Hitachi to the Core” display will give them a chance to learn what Hitachi can do for their bottom line by getting up close and personal with some of the most efficient, reliable and durable excavators and haul trucks at the show, meeting with global product experts and taking the haul truck simulator challenge. In addition, Hitachi will introduce visitors to new technologies and integrated solutions that will reduce overall costs and optimize productivity.

IWT Offers Underground Communications, Asset Tracking and More

Innovative Wireless Technologies Inc. (IWT) is a leading supplier of wireless communication, tracking and data systems for underground mining operations. IWT’s Sentinel system provides real-time, crystal-clear voice communications with minimal setup and low maintenance for maximum productivity and low cost of ownership. The all-in-one digital system supports tracking of people and assets, data from atmospheric and other sensors, and data analytics. Line or battery-powered infrastructure components and handset and tracking tag options provide flexibility to meet unique application and deployment requirements. Tiered solution offerings allow customers to upgrade and expand features as their needs change. The new legacy system interface allows customers to maximize their current communication investment while taking advantage of the advanced range and resiliency provide by the Sentinel network. (Booth 29505 in the South Hall)

Eickhoff Engineers Longwall Shearing Machines

For longwall miners, Eickhoff (Booth 1921) manufactures shearer loaders in four different models for a range of cutting heights from 62 in. to greater than 28 ft. Eickhoff shearers offer the widest range and power, the strongest gearing and innovative automation features.

For room-and-pillar mining and development headings, the company’s continuous miners with unique hydraulic traction drive can cut coal or soft rock from beds that range from 55 in. to nearly 15 ft. The newly advanced hydrostatic transmission on Eickhoff’s continuous miners provides easy overload protection, less shock on gearboxes and less electrical issues, all with a lower cost investment and overall lower maintenance.

The company also offers gearboxes, custom gearing and one-off castings all designed and cast within Eickhoff’s state-of-the-art manufacturing facility and foundry. The company has more than 150 years of experience and it is focused on providing technically superior and cost-effective mining machinery with a global network of technical experts supported through subsidiaries situated in all major coalfields.

Eickhoff will display the latest in shearer technology for longwall mining.

TerraSource Global Presents Options Crushing and Materials Handling

Whether their operations are big or small, mining companies all over the world count on the enduring, end-to-end value they receive by partnering with TerraSource Global (Booth 8618). Broad engineering expertise, in-depth knowledge of industry sectors, precision original equipment manufacturer parts, dependable and local customer-focused service, and a broad application portfolio that offers real product choice from three renowned flagship brands, Gundlach Crushers, Jeffrey Rader and Pennsylvania Crusher. A day at MINExpo isn’t complete without stopping by TerraSource Global’s booth to check out some of its industry leading hammermills, roll crushers and vibrating feeders and talk with the company’s knowledgeable staff about unique business challenges and how the TerraSource team can help customers achieve objectives for growth, efficiency and profitability.

Fenner Dunlop Presents Complete Conveyor Solutions

Fenner Dunlop Americas strives to be a complete conveyor solutions provider. It presents integrated offerings including below and above-ground conveyor belt, idlers and structures, installation, diagnostic services, repairs and belt replacement to customers. Its premium conveyor belts are made in their top-of-the-line factories in the USA and Canada and are held to the highest quality control standards. It guarantees that its product offering will drive value for its customers, maximizing uptime, overcoming hurdles and creating cost savings.

Fenner Dunlop considers itself a complete conveyor solution for coal operators.

Superior Broadens its Scope

Superior Industries Inc., a U.S.-based manufacturer and global supplier of bulk material processing and handling systems, plans to launch several new products at MINExpo International 2016. In the Silver lot (Booth 19100), the manufacturer will display its new Patriot Cone Crusher, TeleStacker Conveyor, mine duty idlers, mine duty pulleys, conveyor drive package solutions from its Core Systems Design group, Chevron Pulley and a brand new mine duty Exterra Belt Cleaner.

Superior will display more than a dozen individual conveyor idler styles for solutions covering every mining application. In addition to rollers from its existing line of CEMA-rated idlers, Superior will display a group of brand new idlers, Mine Duty Idlers, specifically designed for heavy mining applications. For the first time in North America, the manufacturer will showcase a unique double tube roll design. Engineered for applications operating around-the-clock, the double tube design offers increased stability, longer wear life and better bearing protection.

Also new for visitors at MINExpo, Superior plans to display a group of conveyor pulleys from its mine and super duty collections, Mine Duty Pulleys. Engineered using special software, these failsafe pulleys are virtually tested for strength in an application before a single plate is cut at the factory. Specifications include pulley diameters up to 120-in. (3,000 mm), belt widths of the same and shaft diameters up to 24 in. (600 mm).

Superior said its Core Systems Design program offers drive and tail pulley assemblies custom-engineered for a specific application.

In addition to a new crusher and screening machine, Superior will display it’s full line of conveyor equipment.

McLanahan Showcases Wet and Dry Processing

McLanahan (Booth 4257) will feature its latest wet and dry processing equipment, engineered to make producers more efficient, more productive and more profitable. Several new pieces of equipment will be introduced to the market during the show, including the MSP Cone Crusher, MAX Series Vibrating Screen, Vezin Slurry Sampler and more. Additionally, McLanahan will showcase their wear solutions, which are known to increase wear life five to six times that of other parts.

Even with all the exciting pieces in McLanahan’s booth, some equipment is just too big to bring to put on the MINExpo show floor. That is why the company will be utilizing Oculus technology at their stand to put visitors next to life size equipment. Show attendees can stop by and try on the virtual reality headsets to enter a world where they will be able

to see equipment working up close and personal.

With offices in six countries, McLanahan is committed to providing customers with local service and support through their 24/7 Global Response Team. Stop by and talk to McLanahan about a custom engineered solution to increase your uptime and profitability.

High Pressure Longwall Pumps From Hauhinco

Hauhinco (Booth 3027) high-pressure plunger pumps and valves are energy-efficient, robust units designed for continuous operation. The pumps are constructed with high-quality materials, wear-resistant and corrosion-resistant coatings, innovative technical designs as well as the latest manufacturing and inspection processes guarantee low wear and long service lives.

All high-pressure pumps are equipped with a crankshaft drive and integrated helical gearing with circulating oil lubrication. Optionally, every pump type can be equipped with an external lubricating oil supply and a variable frequency drive. As is typical for Hauhinco, every high-pressure pump is available in a foot type and a flange type.

Various volumetric flow rate and pressure combinations are possible with every pump type by simply replacing the pump inserts. As a consequence, Hauhinco units can be adapted flexibly if the conditions and requirements change. All components are easy to access due to the maintenance-friendly design.

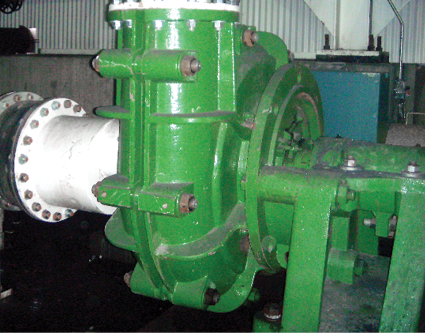

Schurco Builds Mine-duty Slurry Pumps

Schurco Slurry (Booth 5735) manufactures high-quality heavy-duty horizontal slurry pumps, vertical slurry pumps, replacement pump parts for Warman pumps, and provides pump services to a wide array of markets worldwide.

The company specializes in handling the toughest and most abrasive applications, while supplying new slurry pumps with some of the lowest lead times in the industry. The goal is to have the lowest total cost of ownership of any slurry pump manufacturer on the market by offering the greatest value on capital equipment, the highest quality spare and replacement slurry pump parts, and providing unmatched engineering excellence from a company that only focuses on one product: slurry pumps.

With low lead times and attentive customer service, Schurco Slurry is one of the few remaining American ultra-heavy-duty slurry pump manufacturers delivering unmatched quality, engineering expertise and product value. Schurco is a recognized leader in slurry pump manufacturing, pump repairs, pump remanufacturing and quality replacement parts.

Schurco specializes in handling the toughest and most abrasive applications, while supplying new slurry pumps with some of the lowest lead times in the industry.

Longwall Mining Services Offers Ideas for Efficiency Improvements

Longwall Mining Services (LMS) is looking at several was to improve the safety and efficiency of the industry it serves. With this in mind, they have partnered with some premier brands in the industry (Booth 1249).

For longwall miners, the company markets the Bretby cable handling system, the Comtrol communications system and the Plieger Plie-Tech Leg Pocket Fillers — the highest-quality, longest-lasting foam fillers. In addition to conveyor control systems, the company also has MCI mine lighting products that include infrared camera solutions.

LMS also carries Prysmian Mining Cables, Lewis-Goetz hoses and special products and ATB Morley motors, which use a unique and supremely reliable “Barlok” rotor construction. Morley claims to be the premier mining motor supplier in the world. The company is also now partnering with the LinearEdge, “the future of wireless communication,” and MineHubPRO, a mining-based business-process management software system that automates the back office functions.

Cincinnati Mine Machinery

Cincinnati Mine Machinery (Booth 4409) is excited and proud to be part of this wonderful industry and participate with its “Friends of Mining.” Over the company’s long history, it has enjoyed working with its customers. Its mission is to exceed customers’ expectations.

Through continuous improvement, innovative thinking and time-honored values, they deliver quality, reliability and superior performance. With their people, partners and products, they are the strongest link in the mining industry. The company will display several new products at its booth, such as a forged crawler chain for roof bolters and mobile roof supports, the 7.25- x 22-in. Crawler Chain for heavy-duty continuous miners, and their new strongest link, the DA-3522 Conveyor Chain, taking their tensile pull strength up to 275,000 lb. Reliability, performance and exceptional value are what Cincinnati Mine Machinery has to offer.

Columbia Steel Engineers Products for Mining Applications

For dragline mining, Columbia Steel’s (Booth 5819) XtraLife chain’s additional ridge of metal is far greater than that of oval chains. The result is longer link life and fewer premature stress failures. Cast in Columbia’s H-alloys, XtraLife has good resistance to both abrasion and impact. For greater abrasion resistance and even longer wear life, Xtend Process high carbide overlay can be bonded to high wear areas. Columbia engineers will be on hand to help mine operators select the right design and the right alloy from existing inventory — or design a custom solution. All Columbia Steel products are made in the USA and guaranteed for proper fit, performance and customer satisfaction.

For dragline mining, Columbia Steel’s XtraLife chain’s additional ridge of metal is far greater than that of oval chains.

Polydeck Offers Modular Screening Solutions

Since 1978, Polydeck Screen Corp. (Booth 5619) has been a leading provider of modular screening solutions for the mining industries. At MINExpo, the company will exhibit some of its newest products and innovations including:

Metaldex: A new line of modular AR500 steel sections in a range of apertures that fit their PipeTop II stringer system;

PaneLite: A lighter series of screen panels with a strong composite insert that reduces panel weight by nearly 2 lb per square foot;

VST: This patent-pending design incorporates slots at opposing 45° angles creating a zigzag flow that increases retention time, providing increased drain rates per square foot; and

DMax: A series of extreme open-area screen panels that utilize a modified insert configuration that allows more apertures.

Cast members of Discovery Channel’s hit TV show “Gold Rush” will also make appearances at their booth.

Polydeck, seen here at MINExpo 2012, will display its screening systems.

Jennmar Provides Ground Control Solutions

Jennmar (Booth 4249) is leading the way in ground control technology for the mining and tunneling industries. The company will be displaying several core products at MINExpo 2016. Jennmar will have their advanced line of INSTa’L Bolt Anchor Systems, including the Fully Grouted Cable Bolt (FGCB), Fast Anchor 3 steel bolt for strata control that provides quick assembly and secure installation, and a wide variety of cable bolts.

Jennchem, one of Jennmar’s affiliates, will be displaying its Cribs (a pumpable standing support), Cans (custom-made corrugated steel shell filled with specialized cement), PUR (Polyurethane Resin for stabilization of fractured strata and grouting of cable bolts), and one-day Seals (a specialized foaming cement used with a variety of form designs including wood, concrete block, props and mesh).

Flanders Promotes Open Architecture

Flanders (Booth 25215) will launch several new products associated with its Freedom platform, the Flanders open architecture control system, which includes Freedom for haul trucks, Freedom for draglines, Freedom for underground coal transporters, and updated features for Freedom for shovels. Moreover, the company will announce a new machine health reporting system, Invision.

L&H Showcases Enhanced Products

L&H Industrial (Booth 8876) will have a full display of some of their newest enhanced products for the mining industries. Some of the products showcased at the event will include a new hydraulic gearbox design for wheel loaders with through-shaft technology, an improved spline as well as an innovative rotary seal. L&H has redesigned the electric rope shovel straddle mount front idler to reduce bearing stress by 50% and has removed the internal thrust washers; resulting in greater safety with the virtual elimination of splitting the tracks. Finally, a new track design for Atlas Copco drills will be on display, engineered to alleviate inherent “dozer” design shortfalls including reduced steering load and contact force.

Matrix Advances Technology Underground

Matrix (Booth 2829) will demonstrate new enhancements to its IntelliZone proximity detection system. IntelliZone proximity systems, which are used on underground production equipment throughout North America, Africa, and soon, Australia. These systems are designed to be the most production-efficient proximity systems available to the market and are used by the world’s leading underground coal mining companies.

Matrix will also be unveiling its new MineOwl camera and light system. Building on the cutting edge technology the industry has come to expect from Matrix, MineOwl low-light camera systems are available with a variety of options, and can be viewed in Matrix’s simulated underground mine environment.

Along with proven systems such as the METS 2.1 Mine Monitoring System for tracking, communications and atmospheric monitoring, Matrix will also be demonstrating the Monitech machine-mounted methane monitors and laser light curtains.

Martin Engineering Promotes Conveyor Safety

Martin Engineering (Booth 4015 inside/10380 outside) will showcase its latest technology designed for the mining industry including the CleanScrape Cleaner, an innovative metal-tipped belt cleaner that provides maximum cleaning efficiency without compromising the belt, and the Martin Roll Generator, a generator that draws power from the movement of the belt.

Martin will also be introducing its new “Foundations for Conveyor Safety” book. It is the world’s first collection of best practices and joins the company’s Foundations series of books and seminars. This comprehensive 300-plus page textbook is devoted exclusively to conveyor safety and will be available at the show.

Dupline Promotes Safety

The strength of the DuplineSafe Safety Bus (Carlo Gavazzi Inc., Booth 28124) is reliability, simplicity and ability to transmit signals up to 3.1 miles. Dupline’s simple and hardware-oriented communication principle provides a strong platform for a Safety Bus, and the DuplineSafe products are approved by TUV according to EN61508-SIL3 and EN954-1 Cat 4. DuplineSafe’s noise immunity and reliability prevent false trips, while its simplicity reduces human error risks and saves time. The long transmission distance makes it possible to implement plant-wide solutions. Safety diagnostics means machine stops can be fixed faster, leading to higher production efficiency.

Immediate and precise diagnostics mean emergency stop situations can be resolved faster, leading to higher production efficiency. There is a significant reduction in wiring cost on long distance applications. The high noise immunity of the Dupline bus means false trips are avoided. Expansion is easy with simple step-by-step installation of additional safety input modules.

Trolex Monitors Conditions Underground

Trolex (Booth 24524) is a leading global supplier of gas detection, condition monitoring and connector solutions to the mining, hazardous industry and rail markets. Their products are deployed in more than 100 countries to protect miners and assets, and to maximize efficiency. The company offers the latest in wireless gas and dust detection technology, LED lighting and Exd connectors, and provide fully engineered solutions to meet the diverse needs of our customers.