With the technology to monitor any coal mine operation, prep plant, stockpile and overall property virtually every second of each day year-round, it seems strange to consider that some coal ash impoundments still rely on more time-consuming manual methods for keeping an eye on things from both a safety and environmental perspective. The Tennessee Valley Authority (TVA) is working to help change that through both intelligent compaction technology and state-of-the-art monitoring methods.

The Kingston Fossil Plant’s dry ash impoundment.

Both efforts have been under way for some time, particularly since the high-profile December 2008 ash spill at TVA’s Kingston plant in Tennessee that left dozens of homes damaged and three destroyed. While considered one of the largest spills in history with 5.4 million cubic yards of coal ash lost from a dike failure, there were thankfully no serious injuries or deaths.

With the topic of coal ash storage always at the forefront for power facilities, TVA’s environmental scientist and civil engineers, Jason Hill, Nicole Walker and Nicholas McClung recently told Coal Age that making strides in this area was of paramount importance — leading them to implement a more efficient and safer storage technique known as intelligent compaction. Getting to that point meant a lot of testing, placing instruments and gathering as much information as possible on the characteristics of that ash.

The primarily question, the group said, was how to manage TVA’s ash for long periods of time, as well as how to more efficiently compact material and understand its characteristics and movements over months and years. “That event [Kingston] set in motion a chain of events that made TVA [a] leader in coal ash safety to ensure that we’d never have that kind of event again,” according to McClung, a professional engineer and TVA’s manager for risk and quality assurance.

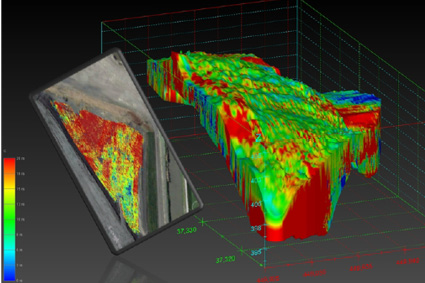

An example of a topographic map created by the intelligent compaction technology.

Working with operations and instrumentation personnel teams across the TVA, one core mission was automating the instrumentation for information collection and, once it was there, to make it real-time. The concept has grown exponentially across all 11 TVA plants, with 7,000 sensors in the field sending data to a GIS database every five minutes.

While initially created outside of the TVA due to IT space, the system is now owned and operated by the utility. It is an ongoing process to keep it at peak performance, and the group is continually building upon it.

“We’re in operational mode,” Hill, TVA’s environmental scientist, said. “We’re always looking at the instruments, procedures with them [plants]…[and] calibrations.”

The network is flexible, so as instruments are added and removed from TVA’s plants, the system can easily incorporate new and abandon old segments.

Proper, effective compaction has helped the utility reduce its environmental footprint while also making its sites safer.

As part of this effort to go high-tech with an old problem, the TVA has also committed itself to moving from wet impoundments to dry storage, something it moved toward even before today’s fast-changing federal regulations were introduced. Its goal is to have all wet impoundments closed in four to six years in favor of dry storage. With that change, the risk of another Kingston-type breach is eliminated. “That’s where the birth of intelligent compaction has come from,” said Walker. “We wanted to make sure material would never go anywhere once [placed].”

That portion of the project began in 2011, when the TVA joined together with Iowa State University to research how to calibrate the ash storage area’s technology for the easiest monitoring. What once depended on individuals to perform in the field and analyze manually (and remotely by sending information to the university, then await a response) TVA can now view via a dashboard with all collected data in one place, the ability to view anomalies in the now ultra-compacted ash pile quickly, and even a camera feed of the compaction roller at work.

Verification of stability can then be achieved by auditing the data, including density, strength, voids and other factors using in-ground vibratory equipment; in short, when things don’t add up, the utility knows that something is amiss with the specific landfill being examined. A system of numbers and associated colors on the monitors also aids in discovering potential problems and staying ahead of issues. The label “cutting-edge” certainly applies, considering that all previous technology and methods simply did not have these capabilities.

The intelligent compaction systems are currently deployed at two TVA sites, and a third is expected to be mobilized later this year. The TVA is aiming to have six landfills outfitted with the system by 2023 or 2024, though that figure could change if the number of plants in its portfolio change in that time span.

“From the very beginning, it was always about safety, of people and environment. [It will also] improve costs to the ratepayer and provide efficiency in the field,” McClung said. “We’re making sure we’re reducing environmental impacts, any impacts, for TVA. In the long run, what we want to do is automate things, reducing the amount of people that need to go get the info. Making it real time — we can then make changes more efficiently.”

The top goal, the group stressed, was indeed safety and to be good stewards to the public and regional communities.

Looking ahead, that goal will not change, and they noted that the TVA is “light years” ahead of the industry in terms of managing ash placement; its role for the future, then, is continuing to make the entire system smarter and better.

“Most of these landfills are going to have to be managed 30 to 50 years; [this] management tool will help us place this in smallest space possible. We will get smarter in terms of understanding ash itself [and] will be learning much more about ash and how it forms,” McClung said, adding that it will gain and share knowledge of ash behavior and improving structural integrity through the use of what it has called an important research tool.

There is also no doubt that someone will always be keeping their eye on the ash. The TVA’s monitoring is 24 hours a day, 365 days a year, with a central control area where the utility’s engineers can see maps, data, messages and more: the Advanced Technology for Impoundment Monitoring (ATIM) at its Chattanooga headquarters. The center is a first for U.S. utilities and includes more than details and real-time views of its sites; it also displays weather, earthquake data, vital maps and more.

“With a few clicks, we can pull up sensor data and see real-time data or watch what’s happening at our impoundments via live video,” McClung said. “What’s most important is that we can share information with everyone who is working the problem.”

The TVA group noted that, to date, the ATIM center has never been activated in response to a real event, only mock readiness drills.

“Having the ATIM process in place demonstrates how serious TVA is about safe coal ash storage,” said McClung. “The ATIM center will provide our executives a single, complete source of information. We can quickly get the support we need to ensure public and environmental safety.”

The Advanced Technology for Impoundment Monitoring (ATIM) center at TVA’s Chattanooga headquarters.

TVA’s Pioneering Spirit

Being a trailblazer for something often comes with the significant inherent challenge of being the first to try, the first to test, the first to report both the positive and the negative outcomes. For the TVA group, they said the idea of flying by the seat of one’s pants, so to speak, was expected.

“In some cases, we were inventing the technology,” Hill explained. “Another challenge was dealing with the instrumentation and monitoring side, and working internally with our IT (information technology) folks. We were trying to bring in a process that hadn’t even been proven as a robust technology.” Getting those individuals to buy into the project and educating regulators on their vision were both obstacles that had to be overcome. As he noted, many must see to believe, and once those stakeholders see, they love — but getting to that point is a key challenge.

“Our dam safety organization, in charge of all dams [and] we’re regulated by them as well…they had an audit from a reputable ASDSO community [with an] instrument/monitoring plan,” he added. “We brought our instrumentation to a world-class rating across the board. We [are now] recognized as being beyond the curve in the dam safety community, far exceeding state/federal guidelines.”

While regulations outline once a month monitoring, the TVA has gotten this down to every five minutes. That’s a long way from a beginning that was strewn with seemingly insurmountable hurdles.

So, what does the future hold? A good bit, according to the group.

In terms of the monitoring instrument, sharing the cutting-edge technology with others and getting feedback from the industry are both important goals.

“I can see others seeing what we’re doing and getting to where we’re at now. We’re constantly developing, always improving,” Walker said, adding that it will always continue to polish and improve the utility’s software tools. “[Changes] may cost us pennies here in comparison to costs of cleanup on a site.”

Another one of the TVA’s safety advancements is ensuring 100% of the ash stack is mapped. The ash map can be likened to today’s tools to an MRI of sorts, allowing it to take a “slice” of information from any point in time to see how the ash was stored at any site and the factors that were at play during that specific time. That may include imperfections or even how heavily it may have rained when that portion of the ash pile was compacted.

Using technology from the transportation industry as a basis, TVA’s hope is that they can not only compact the material more tightly than ever before — improving safety as well as the environmental footprint — that it will also be able to take a figurative page from any site’s history book and learn from it, applying that knowledge to future scenarios.

With 43,560 square feet in an acre, that’s a lot of information to have available at one’s fingertips, and on-demand.

One thing the group has already learned using some of this information is the specific role that water percentage has to compaction; it has allowed it to move toward the best possible percentages with optimal consistency. Of course, as a coal blend changes, so will that spec for the ash.

“It’s dynamic, constantly changing,” McClung said. “We’re consistently looking at that. Moisture is the key.”