Wallace Electrical Systems developed this lower-profile Underground Diesel Generator.

A new low-profile diesel generator could be a game-changer for room-and-pillar sections in West Virginia

by steve fiscor, editor-in-chief

Moving underground coal mining equipment from one section to another can be time consuming and costly. Traditionally, moving a large electrically powered piece of equipment, such as a continuous miner, feeder-breaker or a roofbolter, required the power center to move along with the equipment. The distance the crews could achieve in a shift were limited by the length of the trailing cable that tethers the machine to the power center.

Over the years, different systems for moving equipment have been developed for room-and-pillar sections in the Illinois Basin (ILB), which includes Illinois, Indiana and western Kentucky. One of those involves a mobile diesel generator. While the configurations differ, the machinery tows the generator, which powers and cools the equipment through a set of short trailing cables and hoses. In some mines, scoops tow or transport the generator as it provides the power to tram through the entry.

Now, a new system has been developed for West Virginia. Conditions in West Virginia differ from those in the ILB. The seam heights in West Virginia on average are a little lower and state regulations regarding the use of diesel-powered equipment underground are more stringent. Using the same design principles with a few upgrades, Wallace Electric Systems has manufactured the Underground Diesel Generator. It debuted at the 2019 Bluefield Coal Show and attracted a lot of attention. Miners and regulators alike view this piece of equipment as a potential game changer for underground coal operators.

A tow bar is attached to the front of the machine.

Meeting WV Specs

Using its years of experience supplying similar systems to ILB coal operators, Wallace Electrical Systems developed the Underground Diesel Generator with an eye toward meeting the requirements of the state of West Virginia, which are more rigid than other coal-producing states. “For a diesel engine of this size to operate in underground coal in West Virginia, this will be a first,” said David Wallace, owner, Wallace Electrical Systems. Headquartered in West Frankfort, Illinois, USA, Wallace Electrical Systems has branch offices in western Kentucky and now in West Virginia.

The control panel is similar to a traditional power center.

In this particular situation, 56CSR23 establishes the standards, procedural and interpretative guidelines under which diesel-powered equipment may be used in an underground coal mine in the state of West Virginia.

The Underground Diesel Generator uses a 402-hp/16,000 cfm Tier 3 Mine Safety and Health Administration (MSHA)-certified Deutz engine. “The size of the engine makes it a little more difficult, but this is the first diesel engine gen-set to meet those regulations,” Wallace said.

Wallace had prior experience supplying these units to underground coal operators in the ILB. “We have been further refining the product over the last several years to the point where it caught the attention of underground coal operators in West Virginia.

This system meets those 56CSR23 requirements, Wallace explained. One of the ways Wallace achieved this goal was to develop a proprietary exhaust gas cooling system, which he refers to as the Emissions Control & Cooling System. It’s a dry system that uses a diesel particulate filter without additives.

The Underground Diesel Generator was designed with maintenance in mind. Miners have easy internal access with no special tools. The side panels swing out so that the filters (oil, air, diesel and diesel particulate) can be changed easily. “It’s a major improvement over similar competitive systems and it’s a vast improvement over our early systems,” Wallace said. “Much of the change was driven by how we keep the engine cool.”

The unit also has a built-in cooling system for the equipment, as most of the equipment it will move is water-cooled. The Underground Diesel Generator has an onboard 320-gallon cooling tank with pumps to feed it to the machine in a closed-loop system. A liquid-to-air heat exchanger removes heat from that water, which is pumped through the closed loop at 50 gallons per minute (gpm).

The Underground Diesel Generator is field-configurable for the different conditions found underground in West Virginia. As an example, it has an adjustable height of 45 in. to 53 in. A field adjustable axle height provides improved ground clearance of more than 12 in.

The Underground Diesel Generator has field-configurable output circuits.

This same approach was implemented for the 350 kilovolt-ampere power distribution system by using field-configurable branch output circuit panels. These panels were designed to be quickly interchanged via two external bolts in order to accommodate a continuous miner rather than a roofbolter.

A New Tool for Moves

While it will be used to move continuous miners, feeder-breakers and roofbolters, the Underground Diesel Generator was also designed and upgraded where it could be used to move a Joy Flexible Conveyor Train (FCT), Wallace said, which is actually a much heavier load. “Coal operators will be able to move the FCT without disassembling it,” he said. “They can drive it from one section to another.”

Traditionally, an FCT would be disassembled, loaded on to railcars, delivered to the section and reassembled and that process can take up to a month. This system could reduce this process from a month to days.

A field adjustable axle height further reduces the profile of the machine to a minimum of 45 inches.

Wallace admits he is no expert when it comes to moving equipment underground. His company makes the machines and miners decide the best ways to use them. Some mines hitch the generator to the equipment while others use scoops and all three pieces of equipment move together.

In West Virginia, the same process will probably be quite different due to the state regulations. The generator cannot move while it’s operating, Wallace explained. “So, they will position it and then the equipment will be able to move the maximum length of the trailing cable, which is usually about 750 ft,” Wallace said. “Once it moves a total of 1,500 ft in this case, they will disconnect and reposition the generator.”

The Underground Diesel Generator has a closed loop cooling system for the equipment it powers.

Nonetheless, the equipment is no longer tethered to an electrical power center. It’s fully mobile to a certain extent. The power system in a mine is not portable, it’s fixed. Once a portable underground power center is connected to the system, it’s no longer portable.

Wallace Electrical Systems is looking forward to placing the first Underground Diesel Generator in West Virginia. They are currently working with coal operators and regulators on the certain specifications to assist with the approval process. “We are adding features to the system to assist in that regard,” Wallace said.

The Underground Diesel Generator really earned its stripes in the ILB transporting continuous miners out from the working sections to the surface for a rebuild. “One of our ILB customers would hook it to the continuous miner and they could easily tram it seven miles or so in a couple of shifts continuously if they kept fuel on the unit,” Wallace said. “In West Virginia, we can only carry half the fuel we normally carry on the system due to the state regulations. So, the units in West Virginia will only be able to run four hours.”

Still, the system will avoid the headaches associated with moving a miner while its tethered to the mine’s electrical system. This cumbersome process involves moving a power center 1,000 ft and reconnecting it to the mine’s power distribution system. In this situation, the miners de-energize the power distribution system, move the power center and then reset it. And, as anyone who has done this knows, whenever they re-energize the system, something else seems to fail.

Wallace Electrical Systems has an approved permit number from the State of West Virginia and is in the process of getting the generator certified at a West Virginia mine. The generator has its certification. Coal operators are seeking approvals from state regulators for the various methods with which they want to use this equipment. They are also training miners so they can make these equipment moves as safely and effectively as possible.

Intrinsically Safe Harness Assemblies

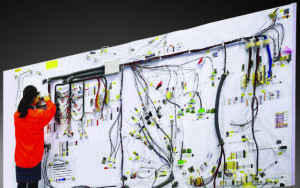

An NAI technician lays out a wiring harness for a mining application.

NAI manufacturing operations in Suzhou, China, recently began the development and manufacture of very complex cable harnesses for installation within large explosion-proof enclosures. These cabinets are placed within mines for the operation and control of variable frequency drives and inverters, which power and control conveyor belts, water pumps, fans, winders and brakes. In addition, they provide alerts and notifications for transformers, motors, cables and other components when they are not operating within the expected temperature range, voltage range or other parameters. All operational drives use NAI interconnect solutions for the transmission of control signals and essentially act as the nerve system for mining operations.

A total of 10 different cable harnesses have been designed, which are used for data communications and control, some with shielding for protection against EMI. Harnesses carrying power are also now in planning and design stages. The typical data/control harness includes more than 100 terminations, while the largest harness has more than 900 terminations. These assemblies have been designed to be very rugged and resilient to various tough environmental hazards. NAI products meet the requirements of the following tests, ratings or standards:

GB3836.2-2010 for explosive atmospheric conditions;

High voltage test at 330V for power cable; and

Connectors are IP67 rated for resistance to dust and water.

One mining equipment supplier recently awarded the design and manufacturing of harnesses and box builds to NAI after producing the harnesses themselves internally. The company finally realized they were not as well suited for this type of work as NAI. They acknowledged that, by using NAI, they reduced their quality risks and manufacturing lead times and they gained access to NAI’s global supply chain for advantages with various components.