Figure 1—Fuel consumption rate before and after PA.

Modular Mining recently demonstrated that its Performance Assurance (PA) program allowed mining customers to uncover and achieve untapped potential, helping them realize the most value from their Modular Mining technologies. Regular site visits, done remotely where necessary to ensure health and safety protocols, conducted by experts in both mining and Modular Mining technology solutions, help mine sites worldwide drive significant improvements in productivity, efficiency and safety.

During each engagement, a dedicated PA team collaborates with mine personnel across multiple levels to develop tailored, flexible and proactive solutions.

Working together, they establish mutually defined goals and milestones, and create and track quantifiable key performance indicators (KPIs). Participating mines, according to Modular, have seen numerous benefits, including enhanced truck productivity, reduced truck queue times, improved net production through shorter shift change duration and lowered equipment maintenance costs.

A large coal mine in Indonesia is the most recent example of the program’s success. It leveraged Modular’s MineCare Maintenance Management system, as well as the DISPATCH Fleet Management System (FMS) and the ProVision Machine Guidance system, to optimize their operations.

Recognizing the erosion of its profit margins resulting from excessive haul truck fuel consumption, the mining company requested help from Modular’s PA team to identify the root cause and improve their fuel burn rates.

The mine also reported excessive oil filter events, identified in real time by its MineCare system, which was severely affecting overall engine reliability. Blocked oil filters indicated heavy contamination in engine oil, resulting from friction-related metal particles and combustion byproducts, which caused the oil to thicken and lose its lubricity and viscosity. As a result, the truck engines were working harder to overcome the oil’s sludgy composition — burning more fuel and causing the engine to run hotter and less efficiently. The overworked engine also reduced the haul truck’s horsepower and caused excessive, unnecessary engine wear, potentially threatening the truck’s long-term durability.

To monitor the mine’s fuel burn rates, the PA team used the site’s existing MineCare system to monitor trends for the affected haul trucks — collecting fuel consumption rates, engine load and payload data.

The team then coached the site’s MineCare users to identify critical issues, such as low injector pressures and oil filter blockages, and established custom, user-defined alarms to notify them, in real time, to these issues.

Finally, the team helped the mine standardize their work order method to ensure proactive action against events affecting fuel burn rates, especially:

Incorrect fuel injector pressure;

Incorrect fuel injector timing; and

Oil filter blockages.

By carefully monitoring, and proactively addressing, potentially critical issues that were directly affecting the haul trucks’ fuel consumption, the PA team and MineCare system helped the site improve their fuel consumption by more than 18%, from an average 373 liters per hour prior to Modular Mining’s involvement to 305 liters per hour (at max engine load and empty payload1) after, as shown in Figure 1.

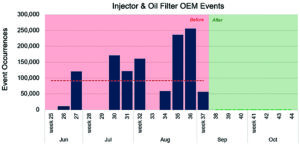

Figure 2—Injector and oil filter OEM events.

This equates to a potential $160,000 fuel savings per year, per truck2. Of the mine’s 39 trucks of this make and model, 21 were affected by injector and oil filter issues; extrapolating the $160,000 annual savings across all 21 affected trucks equated to an annual fuel savings of nearly $3.4 million.

Additionally, since the mine’s maintenance team is now monitoring for these potential issues, and leveraging the MineCare system’s user-defined alerts to identify problems before the OEM sensors did, they were able to pinpoint and remedy these issues before they could become major inhibitors of efficient fuel consumption. As a result, the number of fuel injector and oil filter blockage events were reduced from a peak of 255,000 OEM events per week (before Modular Mining’s involvement) to zero OEM events per week after (See Figures 2 and 3).

Figure 3—Average OEM Event.

Fuel represents a large portion of many mining organizations’ operating costs. By optimizing their fuel consumption and minimizing their unnecessary fuel burn, this coal mine, with the help of Modular’s PA program, was able to reduce its average fuel consumption by more than 18%, saving an estimated $3.36 million in fuel costs per year across its fleet of haul trucks.

1 For consistency, conditions recorded at engine load=100% and payload =0 metric tons.

2 Fuel calculation: 18% x 3,700 liters per tank x US$0.8 per liter x ~300 days operation per year (~80% availability).

This article was written and submitted by Modular Mining.