By Caren Caffrey

While many companies struggle to contain costs and reduce their environmental footprint, quite a few underestimate the value found in keeping oil clean and dry. Oil is traditionally changed at recommended time intervals rather than when the key features of the lubricant, such as AW and EP additives, no longer function. Removing or reducing the primary contaminants responsible for additive consumption and oil degradation will extend the life of the lubricant and the equipment it is designed to protect.

Most oil problems can be attributed to the following types of contaminants: • Particulates like dirt and wear metals generate abrasive wear and cause machine breakdowns.• Moisture/water from condensate or process conditions creates micropit- ting and cavitation, which lead to spalling and fatigue wear.• Oxidation products like varnish and sludge lead to “sticking” valves and dirty vessels.

In a medium-loaded oil system, research shows that about 70%-80% of the particulates are below 5 microns (µm) and almost 90% of the particulates are below 10 µm in size. If the mechanical system in question has a clearance zone that is less than 10 µm, these particles get caught in the boundary zone and are slowly ground down until they are small enough to pass through the metal cracks. Elimination of these small particles through effective filtration improves machine productivity exponentially.

In the real world, maintenance teams must balance proactive, preventative maintenance opportunities against the constant demands of production and cost of downtime. For large mobile equipment such as a haul truck, the costs of repairing a wheel motor can be enormous, easily exceeding $250,000 per day. If needed parts are not readily available, these costs can quickly skyrocket into the millions.• Lost production: $190,000+ per day• Oil change: $3,500-$15,000• Minor repair (seal replacement): $90,00-$130,000• Major repair (seals, bearings, sleeves): $230,000-$260,000• Wheel motor replacement: $650,000- $780,000 (Lead time: 1-21 days)

Proactively cleaning key lubricant systems rather than simply changing oil at predetermined time intervals will reduce maintenance costs and maximize equipment productivity. The CJC Mobile Flushing Unit was specifically designed to handle the highly viscous gear oils with the very low temperatures found in the mining industry.

Proactively cleaning key lubricant systems rather than simply changing oil at predetermined time intervals will reduce maintenance costs and maximize equipment productivity. The CJC Mobile Flushing Unit was specifically designed to handle the highly viscous gear oils with the very low temperatures found in the mining industry.

Field tests have proven the CJC Mobile Flushing Unit will quickly clean lubricants from ISO VG 32 to ISO 680+ during routine PM service intervals. Clean oil from the heated reservoir is pumped at approximately 3.5 gpm (800 l/hr) through the gearbox (rear differential, planetary, etc.) pushing contaminated oil back through the cellulose depth filters. The 3 µm CJC MFU Filter Inserts capture approximately 50-60 lb of particulates, dirt and varnish while adsorbing residual water. Oil cleanliness is continuously measured with the online CJC Oil Contamination Monitor. This unit is versatile enough to work in the confines of a shop or the harsh environments found in the most rugged job sites.

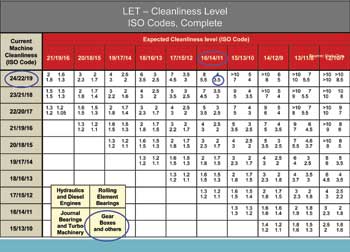

The CJC Mobile Flushing Unit has been tested in some of the harshestclimates. In one example, Mobile SHC 680 gear oil from a 320-ton Komatsu 930E haul truck was flushed in the field at below freezing temperatures(-4˚C). Within 90 minutes, the con-taminant level was reduced fromISO 25/25/23 (>16 million particlesat 4 µm) down to an ISO 16/15/11 (<64,000 particles at 4µm). Based on the following Life Extension Table published by Noria Corp. (See p. 52), this will essentially extend the life of the lubricant and equipment by 3.5 times.

The CJC Mobile Flushing Unit has been tested in some of the harshestclimates. In one example, Mobile SHC 680 gear oil from a 320-ton Komatsu 930E haul truck was flushed in the field at below freezing temperatures(-4˚C). Within 90 minutes, the con-taminant level was reduced fromISO 25/25/23 (>16 million particlesat 4 µm) down to an ISO 16/15/11 (<64,000 particles at 4µm). Based on the following Life Extension Table published by Noria Corp. (See p. 52), this will essentially extend the life of the lubricant and equipment by 3.5 times.

When another operation went to fill a new Cat 7495 shovel with oil, they realized the new oil at ISO 23/19/14 was eight times dirtier than the OEM requirement of ISO 19/17/14. Thus, they could not transfer oil to the shovel until it had been cleaned without voiding the warranty. After several attempts to clean and transfer the oil through the on-board filters, a CJC Mobile Flushing Unit was brought in. Each 200-l (52-gal) batch of oil was cleaned to ISO 14/13/11 within 30 minutes and then transferred to the shovel. By pre-filtering the oil, the company was able to complete the fill process within a week rather than a month.

One maintenance group implemented “mini-PM” sessions on Cat 793 haul trucks every 500 hours. Using the CJC Mobile Flushing Unit, they reduced the oil contamination level from an average ISO 22/20/17 (2 million-4 million particles at 4µm) to ISO 17/15/12 (<130,000 particles at 4µm) within the allotted 8-hour PM time frame. Flushing the oil allowed the company to extend oil change intervals from 18,000 hours to 25,000 hours. Using historic operating rates and wheel rebuild intervals, this group predicted that they will save $380,000 on wheel rebuild costs and another $100,000 on reduced oil consumption, labor and downtime annually.

The CJC Mobile Flushing Unit removed 98% of the particulate contaminants from the SAE 60 Final Drive Axle Oil in the planetary/differential gear system on a Cat 797B haul truck within 5 hours. This business unit traditionally changed the oil in <2,000 hours at a cost of approximately $15,000 per vehicle. By reducing the particulate contamination from ISO 22/20/15 (2 million-4 million particles at 4µm) to ISO 16/15/12 (<64,000 particles at 4µm), they expect to achieve a life extension on the oil and equipment of 2.5 times. Based on the fleet size, eliminating one or two oil changes per year on each vehicle will generate savings of aproximately $1.5-$3 million, respectively.

The CJC Mobile Flushing Unit removed 98% of the particulate contaminants from the SAE 60 Final Drive Axle Oil in the planetary/differential gear system on a Cat 797B haul truck within 5 hours. This business unit traditionally changed the oil in <2,000 hours at a cost of approximately $15,000 per vehicle. By reducing the particulate contamination from ISO 22/20/15 (2 million-4 million particles at 4µm) to ISO 16/15/12 (<64,000 particles at 4µm), they expect to achieve a life extension on the oil and equipment of 2.5 times. Based on the fleet size, eliminating one or two oil changes per year on each vehicle will generate savings of aproximately $1.5-$3 million, respectively.

Declining oil consumption and the elimination of metal filter canisters from landfills will ultimately reduce the organization’s environmental footprint.

About the Author

Caffrey is an account manager–mining with C.C. Jensen. This article was adapted from a paper she presented at the Haulage & Loading 2013 conference, which took place during May in Phoenix, Ariz.