“Work Safe.” While an important statement, it is one heard so often that its impact can get lost in the repetition. The gravity of the reminder, and how crucial working safe is to every worker and their peers, can become more hollow over time in even the most receptive ear. That is in part why the idea of the safety initiative was born; safety through behavioral changes, self- and peer-reporting and even award programs and incentivizing safety carries much more weight and action behind it than just telling someone to make sure their work day is safe.

Putting that responsibility of increased safety in the hands of those on the front lines has been a goal for a team of researchers at the National Institute for Occupational Safety and Health (NIOSH), which recently released the newest way for any mine to identify and record ergonomic deficiencies in the workplace and mitigate risks for everyone: the ErgoMine app.

ErgoMine, an audit tool available for Android that the research group released in April of this year, was designed specifically for mining and, in addition to collecting data on how future health and safety-related problems can be avoided, it can help mines to conduct audits before and after changes are made to its processes to see the true impact in real-time.

While the word audit has a connotation of complexity, the app basically works by asking the user questions about their task, how it is being done, and the conditions in which they are working. Once the input is received, ErgoMine can then produce recommendations for improvement and a report can be forwarded as needed for review. The app’s user-friendly modules include bagging and maintenance/repair as well as a dedicated segment for haul truck operations.

Operations can access existing audits anytime via the ErgoMine app.

A Comprehensive Look at Hauling

From training and policy, the haul road design itself and the mine pit, to inspections, ingress/egress, driving habits, cab design, and loading/dumping, ErgoMine’s eight-module Haul Truck Audit segment includes nearly every aspect of the machine and its environment. Each section contains anywhere from a few to more than a dozen questions to help the application’s algorithms process the specific situation. Some questions include:

- What topics are covered in your mine’s haul truck driver task training?

- Are speed limits posted on the dash of the haul truck?

- Have employees reported the presence of excessive dust clouds that reduce driver visibility on haul roads?

- Are road grades greater than 10% present?

- Is there a standard form to document the preshift inspection of the haul truck?

- Are you, as the driver, provided with adequate time to perform a comprehensive preshift inspection?

Some questions may require just one’s physical inspection or best memory, while others may require additional tools such as a tape measure to record distances. After completing the questionnaire, the user may receive a response similar to this example:

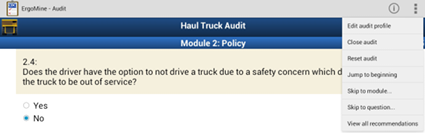

The audit action menu provides a number of options for the user.

“You indicated that road grades are not designed to accommodate the equipment with the least braking capability or you do not know how the road grades are designed. Regarding grade or steepness of a road, it is important to have compatibility between road conditions and equipment capability. A critical concern for haul truck safety is the ability of the brakes to function effectively on downgrades to avoid loss of control of the vehicle. Different equipment with differing performance characteristics will use the haul roads. Thus, roadway design must accommodate the equipment with the least, or the most critical, braking capability, which are usually large haul trucks.”

With one of many responses such as the above will be the opportunity to share the results of the audit recommendations via a report document. The user can then share it with others, or safety personnel can use the results to distribute important details to miners and managers in subsequent safety meetings; this can be done via email or even exported as an HTML file and sent to Google Cloud Print.

With safety and health hazard mitigation a consistent hot topic across mining, the NIOSH research group noted that the audits need not be completed only by upper-level managers; in fact, any mine worker can easily complete the questions with the audit tool and easily receive the app’s recommendations, then put the recommendations into action. By doing this, in addition to quicker feedback, mine staff stands to gain much more insight from the effort, and in higher detail, than if an expert practitioner had come on-site to perform a similar audit project.

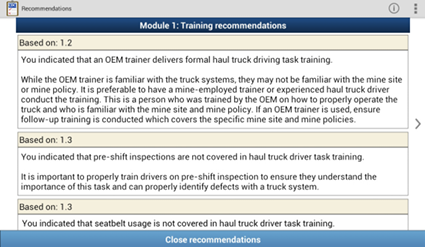

An example of a recommendations page in the ErgoMine app. The results can easily be forwarded to others for review.

NIOSH has already completed field testing of the app at various mine sites, using feedback from the test groups to polish the capabilities and also address any potential shortcomings prior to its April release. The research group said it is also tracking usage of the app since going live. For mines already using ErgoMine since its release, the group highlighted that in addition to opening new audits as they are needed, any prior audit can be opened and examined at any time. To open an existing audit or to edit it, simply look for the Audits page to find a list. A notes function is also part of each of the app’s modules, as well as a location finder (note: if the GPS service is not working, check the device’s settings).

According to NIOSH, the app offers a tool for the industry to identify issues without formal training. Its suggestions can aid workers in the prevention of musculoskeletal injuries and promote health, safety and efficiency.

If any operation would like to conduct an audit manually — be it haul road or maintenance/repair — the modules and recommendations have also been made available for download and printing in classic clipboard-and-pencil style at www.cdc.gov/niosh/mining/works/coversheet1906.html.

The ErgoMine app was created by NIOSH’s Pittsburgh Mining Research Division. It works on both smartphones and tablets with the Android platform (Honeycomb 3.2 and higher) and is available for download at the Google Play store. The app, which is capable of collecting, storing and exporting all of the audit’s recommendations, supports all screen sizes, but a 7-in. screen or larger tablet is recommended in order to best view the modules as well as the additional linked PDF resources.

NIOSH is also overseeing the support of ErgoMine. The NIOSH Mining program can be reached at NIOSHmining@cdc.gov.

Disclaimer of Liability: This NIOSH developed software is provided “as is” without warranty of any kind including express or implied warranties of merchantability or fitness for a particular purpose. By acceptance and use of this software, which is conveyed to the user without consideration by NIOSH, the user expressly waives any and all claims for damage and/or suits for personal injury or property damage resulting from any direct, indirect, incidental, special or consequential damages, or damages for loss of profits, revenue, data or property use, incurred by you or any third party, whether in an action in contract or tort, arising from your access to, or use of, this software in whole or in part. No further development or upgrades for this software is planned.