The Babcock & Wilcox Co. (B&W) has been awarded a United States patent for a Submerged Grind Conveyor (SGC) system, a cost-effective coal ash conveyor system that enables utilities to reduce water usage and their reliance on ash storage ponds, which could result in significant cost savings for utilities.

The Babcock & Wilcox Co. (B&W) has been awarded a United States patent for a Submerged Grind Conveyor (SGC) system, a cost-effective coal ash conveyor system that enables utilities to reduce water usage and their reliance on ash storage ponds, which could result in significant cost savings for utilities.

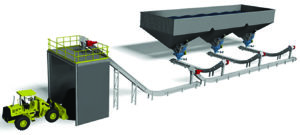

The design of B&W’s SGC system makes it an ideal choice for replacing existing bottom ash systems nearing end of operational life or experiencing high operation and maintenance costs. The system uses existing infrastructure to help plants upgrade faster with minimal impact to operations and will help support future Coal Combustion Residual (CCR) management rules and Effluent Limitations Guidelines (ELG).

“Our SGC system is simplified and cost-effective versus competitors’ bottom ash solutions,” said Heather Muckley, director of B&W’s ash and material handling business and project development. “The system also helps our customers meet the ELG zero-discharge requirements in a minimally intrusive manner.”

The design of B&W’s SGC system should also improve operation efficiencies and maintenance costs over traditional high-pressure sluice systems. The B&W SGC system is designed to work in connection with a plant’s existing ash hoppers or slag tanks, which allows for smoother retrofit into tight spaces. Compact mechanical conveyors replace the old high-pressure sluice system, reducing transport water needed to convey ash. The minimally intrusive design permits quicker installation as compared to other under-boiler solutions.

www.babcock.com