Arch Resources now operates two longwalls in West Virginia, Leer South and Leer (above).

America’s newest longwall begins production

Arch Resources recently commenced production at its new Leer South longwall mine in Barbour County, West Virginia. When fully ramped, the mine is projected to produce up to 4 million tons per year (tpy) of premium-quality, high-vol A metallurgical coal.

“This is a momentous development for Arch Resources, our global steel customers and the state of West Virginia,” President and CEO Paul A. Lang said. “We expect Leer South to quickly become one of the most competitive metallurgical mines in the United States, and to serve as an essential feedstock for global steel production for the next two decades or more.

“At the same time, we expect this world-class operation to act as a cornerstone of the northern West Virginia economy over that same timeframe, providing more than 500 permanent, well-paying jobs while supporting countless other regional businesses.”

The state of West Virginia played a pivotal role in the development of the project, according to Lang. “We want to thank Gov. Jim Justice and the state of West Virginia for their great vision in facilitating this significant, job-creating project,” Lang added. “We could not ask for a better partner as we continue to intensify our corporate strategic focus on metallurgical coal and global steel markets.”

Arch commenced work on the new mine just 2.5 years ago and invested approximately $400 million on the buildout.

“The Leer South team has done an extraordinary job in bringing this large, multifaceted project to fruition in the face of a pandemic and in the midst of a rising material and labor cost environment,” COO John T. Drexler said. “Because of the tremendous focus and dedication of the entire Arch operations team, Leer South is ramping up at a highly strategic time, with the global economy rebounding and with steel-makers struggling to secure sufficient supplies of high-quality metallurgical coals.”

As anticipated, the Leer South longwall started up at the end of August following a planned 30-day outage that accommodated the

upgrading of the material handling system and is currently in the process of system testing and integration, with the expectation that ramping up will continue throughout the month of September. Arch expects Leer South to make a significant contribution to production volumes in the fourth quarter of 2021, and to ramp up to full production mode by the start of 2022.

Kestrel recently moves its longwall (above) to a new panel in 22 days.

Kestrel Sets Records for Longwall Moves

Australia’s Kestrel Coal Resources recently reported they completed their latest longwall move at the Kestrel mine in 22 days, setting a new record for Kestrel. The 414-m face had 204 2-m roof supports (shields). Roughly 10,000 tons of equipment was transported 3.5 km underground. On startup, the new face retreated 22 m in two days.

“For this longwall move, we really worked as one and utilized the skillsets across all our teams to deliver an exceptional result for the mine,” said Dan Proffitt, general manager of operations.

Located 40 km north of Emerald in Queensland’s Bowen Basin, Kestrel is one of the largest underground met coal producers, mining more than 7.1 million metric tons per year (mtpy). The mine was founded in 1992 and Kestrel has operated the mine since 2018. Kestrel Coal Resources is a joint venture between EMR Capital and Adaro Energy (80%) and Mitsui Coal (20%).

With belt conveyors capable of handling 3,500 mt per hour (mtph), Ketsrel has produced as much as 1 milion mt per month. The current longwall system is an all Caterpillar face, which includes the shields, armored face conveyor, stageloader and an EL3000 shearer, capable of mining up to 3,000 mtph. The longwall face is automated and the panel length is 3.5 km (11,500 ft).

Kestrel uses a Sandvik MB650 bolter-miner on development with 15-mt Joy shuttle cars. The development sections have achieved 7 m per hour of advance.

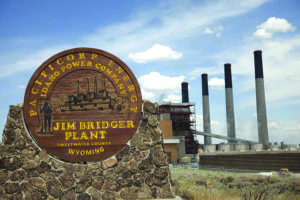

Wyoming’s Jim Bridger power plant will idle two of four units by 2028.

PacifiCorp Will Close Jim Bridger Longwall Mine in November

Bridger Coal Co. plans to permanently close Wyoming’s only underground coal mining operation as soon as November 19. Jon Brown, general manager-mines for Pacific Minerals Inc. (PMI), a subsidiary of PacifiCorp, issued a Worker Adjustment and Retraining Notice to Rock Springs Mayor Tim Kaumo on September 3, saying nearly 100 miners will be affected by the decision.

The Jim Bridger longwall mine supplied roughly 2.4 million tons of bituminous coal to PacifiCorp’s Jim Bridger power plant. Already during 2021, the underground operations have produced 1.4 million tons, according to Mine Safety and Health Administration statistics. The plant also burned coal from Bridger’s surface operations (1.5 million tons in 2020 and 578,000 tons in H1 2021) along with coal from the Black Butte mine. Black Butte produces roughly 2.2 million tons per year.

In 2019, PacifiCorp, as part of an integrated resource plan, announced plans to close Unit No. 1 at the Jim Bridger power plant by the end of 2023 and Unit No. 2 by 2028. Units Nos. 3 and 4 were expected to operate through 2037.

Bridger Coal Co. is a joint venture between PMI and Idaho Power Co. PMI holds a two-thirds interest in the joint venture. PacifiCorp was bought by Warren Buffet’s MidAmerican Energy in March 2006.