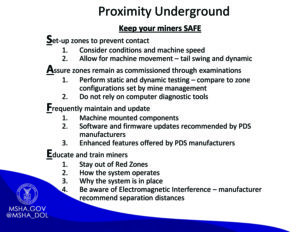

Figure 1—The SAFE program for Proximity Detection Systems.

The agency answers COVID-19 compliance questions from mine operators

by steve fiscor, editor

The U.S. Mine Safety and Health Administration (MSHA) recently held a quarterly stakeholders call. In addition to updating the industry on recent incidents, the new organization, training and the regulatory agenda, the agency addressed concerns related to the coronavirus (COVID-19). Mine operators are reacting quickly. Some are idling operations for a short period with the hope of reopening with a healthy workforce, while others are continuing to operate while complying with the guidelines that have been issued. The agency said it’s doing the same and trying to be a little more flexible as the pandemic spreads.

In his opening remarks, Assistant Secretary for Mine Safety and Health David G. Zatezalo discussed the COVID-19 threat before addressing the usual business. “The world has changed a lot since our last quarterly conference call in mid-December,” Zatezalo said. “COVID-19 has changed the way we live our everyday lives on many fronts. We must do all we can to fight this dreaded illness using every tool at our disposal. We have posted materials on the MSHA website [www.msha.gov]. You should follow the President’s Coronavirus Guidelines for America and the CDC [Centers for Disease Control] guidance. MSHA suggests maintaining the social distance of 6 ft wherever possible. This means no crowding personnel carriers, hoists and other means of transport.”

“Please stay home if you feel sick,” Zatezalo said. “The American mining industry has experienced several cases of COVID-19, but we are not aware of any miners who have died due to it. However, we know the situation could get worse before it gets better.”

During the stakeholder call, the agency reviewed the hazards that frequently cause incidents at mining operations. So far this year, the American mining industry has suffered six fatalities. “That’s six too many in my view,” Zatezalo said. They also discussed the recent realignment of its enforcement division providing details on the new regional arrangements. The agency gave an update on developments with training and reviewed the rulemaking agenda for 2020.

Figure 2—Powered haulage tops the list so far for 2019.

Collision Avoidance and Proximity Detection

Wesley Shumaker, chief of the applied engineering division for MSHA Technical Support’s Approval and Certification Center, discussed collision warning systems for surface equipment and proximity detection for underground mining. “These technologies are engineered solutions for many of the powered haulage and mobile equipment involved accidents that take place each year,” Shumaker said.

“We encourage mine operators to investigate and implement these systems,” Shumaker said. When selecting a system, he explained that operators need to evaluate the various needs for both heavy equipment and light vehicles. They should also consider stationary objects, mine conditions and surface features. He also reminded operators to remember the different types of pedestrians like contractors and visitors.

MSHA Tech Support has been involved with several investigations of fatalities and other incidents related to proximity detection systems (PDS) for underground machinery. “We have found that PDS will provide protection,” Shumaker said. “The issues are related to the PDS not being used properly or the PDS not being maintained properly.”

Examples of a PDS not used properly would include not wearing the wearable component, miners overriding the system or other attempts to intentionally defeat the system. When a PDS is not maintained properly, the zones are not maintained as commissioned, the machine-mounted components may be installed improperly, or the static and dynamic testing was inadequate.

MSHA Tech Support has developed a program to protect miners underground with proper use and maintenance of PDS, known by the acronym SAFE (See Figure 1).

Powered Haulage Still Tops the List

Marcus Smith, chief of accident investigations for MSHA, led the discussion on fatal accidents, noting that Powered Haulage already tops the list for 2019 (See Figure 2). “Powered haulage is a broad category that takes into account fatalities that occur with equipment used for haulage that is powered by an engine or a motor, such as trucks, loaders, conveyors, shuttle cars, etc.,” Smith said. “It accounted for 26% or seven out of 27 fatalities last year. Powered haulage, unfortunately, has been a leading category in years past. In 2018, it accounted for 13 of the 28 fatalities or 46%.

“This is an area where we need to remain ever-vigilant,” Smith said. “When we look at best practices, we think of seat belts, communications, brake maintenance, berm, safe speeds properly posted, adequate examinations of working areas and lock-out/tag-out practices around conveyor systems.”

Machinery is also high on the list. These fatalities are caused by a component of the machine or the machine itself.

Last year, the American mining industry had an elevated number of electrical-related fatalities. “We need to continue to emphasize lock-out/tag-out and, when miners are dealing with high-voltage, stress the need to ground the system,” Smith said. “It’s important to remove the energy and tag it out to alert the other miners that work is currently being performed.”

New MSHA Regional Arrangement

MSHA recently reorganized its regions combining coal and metal/nonmetal enforcement. During December 2018, the agency promoted Tim Watkins to administrator for coal and metal/nonmetal mine safety and health enforcement. He has overall responsibility for all aspects of enforcement. Previously, Watkins served as deputy administrator for coal mine safety and health and prior to that, he was the district manager for Coal District No. 12 in West Virginia.

Watkins discussed MSHA’s new regional arrangement. Referring to a color-coded map (See Figure 3), he noted the three new regions: East, Central and West. Historically, MSHA had two administrators (one for coal and one for metal/nonmetal) and each of them had two deputy administrators. All of them were stationed at MSHA headquarters in Arlington, Virginia.

“With the One MSHA Initiative, we now have one administrator,” Watkins said. “And, we are now in the process of establishing three regional administrators. One of those positions is currently open. The eastern region includes the Warrendale, Pennsylvania, Mount Pleasant, Pennsylvania, Morgantown, West Virginia, Beckley, West Virginia, Pineville, West Virginia, Norton, Virginia, and Birmingham, Alabama, districts. We are in the process of selecting an administrator for the East Region, which will be stationed at the National Mine Safety and Health Academy in Beckley. Currently acting in that position is Scott Mandeville, who is also the District No. 4 manager.”

The Central Region includes Duluth, Minnesota, Vincennes, Indiana, Madisonville, Kentucky, Barbourville, Kentucky, and Dallas, Texas. The Central Region administrator is David Weaver and he is stationed in Dallas.

The West region has three districts: Vacaville, California, Denver, Colorado, and Lakewood, Colorado. The Western Regional administrator is Brian Goepfert and he is stationed in the Denver office.

“The reporting structure for the districts remains the same,” Watkins said. “Contrary to some rumors, MSHA is not doing away with the district manager positions. The districts will report to their respective regional administrators. The three regional administrators report to me.” Watkins is based in Arlington and his direct reports are positioned in the field. He believes that placing the regional administrators in the field promotes better oversight and more consistency across the districts.

Prior to the call, MSHA asked stakeholders to submit questions. Watkins said most of the questions revolved around training issues. They could be summarized as: What allowances will MSHA make for training compliance during the COVID-19 pandemic? “MSHA will extend the timeframe for renewal of annual certification for at least as long as the president’s emergency declaration is in effect,” Watkins said. “Exemptions to certifications will not be granted, but the due dates will be extended for at least as long as the president’s emergency declaration is in effect. This exemption does not apply to new miner training. It’s imperative that new miners are properly trained before going to work.”

This extension would also apply to time-sensitive certifications, such as mine rescue, CPR recertification, electrical, etc., Watkins explained. “If mine operators have any questions regarding a specific recertification, please reach out to the district manager or regional administrator for advice. We are trying to be as flexible as possible during the pandemic.”

Figure 3—MSHA reorganizes into three regions.

Training Programs

Kevin Deel manages MSHA’s Educational Field and Small Mine Services (EFSMS) Group. “We have received a number of calls from trainers looking to improve their programs during the downtime,” Deel said. He wanted stakeholders to know that the EFSNS training specialists are still working.

“They are not currently visiting mine sites, but they are available by phone or email to assist with training needs,” Deel said. “Some specialists are in their offices and some are teleworking.”

Mine operators can reach the EFSMS training specialists in one of two ways: by calling the local MSHA field office or visiting the MSHA website and selecting the training tab (See Figure 4), which has details about programs and contact information.

Deel answered the two most frequent questions he has received:

Q: Will we be allowed to perform MSHA annual refresher or new miner training using Zoom, GoToMeeting or Webinar-style learning systems?

“During the pandemic response period, MSHA will be flexible with the use of online training,” Deel said. “Operators need to work with district managers as far as what type of training would be conducted.”

Q: With the emergence from COVID-19 shutdown, whenever that might be, there may be a huge demand for mine props? Is there a particular effort that will be covered that will permit miners that are a bit out of practice returning to 12- to 16-hour shifts?

“This is a valid safety concern,” Deel said. “The amount of time needed for refresher or task training relates to the amount of time the miners were away from the job. We hope operators will properly assess that need and provide adequate training.”

Regulatory Update

The stakeholder call concluded with Rosalyn Fontaine, acting director for the office standards, regulations and variances, briefly discussing upcoming policy changes. She reminded everyone that the final rule for Electronic Detonators became effective on March 16, 2020. During 2020, MSHA will issue a final rule for Refuge Alternatives for underground coal mines related to the limited reopening of the record, Fontaine said.

MSHA will consider a proposed rule to streamline the electronic product approval process (Part 18 Approval). The agency will consider a proposed rule related to Non-Permissible Surveying Equipment. They will also consider a proposed rule regarding a potential safety program for mobile equipment operating at surface coal imines and surface areas of underground coal mines (Powered Haulage Safety Program).

As far as Respirable Quartz, MSHA held a meeting with the National Institute for Occupational Safety and Health (NIOSH) in February and decided to organize a stakeholder workshop for the autumn of 2020. “For any further updates, keep your eyes open for the spring regulatory agenda,” Fontaine said.

Zatezalo closed the conference call by saying, “we are all stakeholders in miner safety and as a group we can reduce the number of injuries and deaths in the American mining industry. Together, we can do our best to defeat the deadly COVID-19 that threatens miners.”

Watkins Fields Questions from Stakeholders

Q: Could you clarify if COVID-19 is a recordable illness if contracted at work?

A: Generally, no, unless it can be demonstrated that COVID-19 was contracted at work.

Q: How is COVID-19 affecting MSHA’s operations?

A: MSHA has limited its activities to mission-essential work only that includes Band-aid inspections, serious accident investigations, imminent dangers and serious hazard complaints. All other activity will be considered on a case-by-case basis.

Q: Will MSHA inspectors follow CDC requirements for social distancing when conducting their inspections?

A: MSHA follows the President’s Coronavirus Guidelines for America, which are based on the CDC guidelines … as well as the guidance that can be found on the Department of Labor website. We continue to update personnel and our website links with any new information on the virus and policy as it develops.

Q: What plans do you have to address large groups gathering at meetings of mine employees in line-up rooms?

A: MSHA encourages mine operators to abide by the CDC guidelines and social distancing guidelines. The agency has instructed its inspectors not to host safety talks with large number of miners.

Q: MSHA inspectors are bypassing the security gates, not stopping at the front office to check in, and heading straight to talk with miners directly. Could this practice be stopped so that the inspectors can be screened for COVID-19?

A: MSHA supports the proactive approach that most operators have taken to reduce the spread of COVID-19. Many operations have implemented employee screening when they come on to the mine site. MSHA encourages its inspectors to participate in these screenings on a voluntary basis and will continue to do so.

Q: Does MSHA have a suggestion to minimize the spread of germs via the paperwork during this time?

A: Many operators are using electronic means to store their records. If everyone did the same, that would eliminate the need for physical contact and MSHA encourages them to do so.

Q: Will MSHA conduct dust/noise inspections during these difficult times? If so, how do they plan to follow the CDC guidelines of 6 ft?

A: These requirements are part of our mandated inspections. We have instructed our inspectors to comply with established guidelines and social distancing guidelines as much as possible. The inspectors have been instructed to lay the instrument down and wipe it off with a disinfectant to best of their ability and allow the miners to place the devices on their person. At the end of the day, the process would be reversed. We understand that this may not work in every case, but to the extent possible, we will comply with all applicable guidelines.

Q: Confirm MSHA is accepting notification letters from mine operators with multiple mine ID numbers that may change the status of a mine without being able to provide the two-week lead time.

A: Yes, MSHA will accept multiple indetification numbers on a single notification letter as long as the effective dates of the status change for each operation is clear.

Q: Will an individual inspector visit more than one mine? If so, what will be done to reduce the chance of exposure from one mine to another?

A: When an inspector needs to visit more than one mine, the agency is instructing them to comply with all applicable guidelines.

Q: Has there been any thought to dust sampling requirements, 30-shift averages and adjusting the amount of required samples?

A: MSHA realizes that production for many mines has been reduced and the agency will take that into consideration.

Q: With the shortage of N-95 masks, is there a recommendation for an equivalent type of respirator that miners should use?

A: The respirators used in the mining environment for compliance must be approved by NIOSH.

Q: Why did the Q2 E01 inspections start early in some districts?

A: MSHA’s mandate is to do four inspections per year at underground mines and two inspections per year at surface operations. There is no requirement that the agency follow a specific calendar quarter to comply with this mandate.

Q: What about dust testing with all the germs floating around the train on dust pumps?

A: To reduce the possibility of [contamination], MSHA is rotating the sampling units.

Q: Can you please provide the industry with a PIB, PIL or preferably a PPL temporary in nature concerning the extension in annual refresher training?

A: MSHA does not believe that a temporary PPL is necessary. The agency has announced the extension guidelines on its website: www.MSHA.gov.

Q: What do we do if we can’t get PPE for the miners?

Miners should not be exposed to hazards that PPE could prevent. Operators should plan work assignments accordingly. If you have any specific issues, please communicate them with your respective district manager or regional administrator.