OmniPro Collision Avoidance System operates as a single-, dual- or three-camera system. Announced in November, it has been deployed to small mobile mining equipment and is currently being trialed on large trucks. (Photo: Matrix Team)

The newest systems have fewer parts, require less infrastructure, and are less intrusive

by jesse morton, technical writer

The latest headlines on the collision avoidance systems made by the top suppliers in the U.S. show a trend in solutions that are easier to install and operate. They have fewer parts, require less infrastructure, and are less intrusive. Added to the list of benefits offered is fewer nuisance alarms and improved overall operability. Miners new to such systems will find the barriers to adoption to be minimal, and the value added to be maximal, the suppliers said.

Matrix Rolls Out OmniPro

Showcased at MINExpo, the new OmniPro Collision Avoidance System illustrates the maxim that simple is better, Matrix Team said.

The system requires no preexisting infrastructure, is easy to deploy, and is an “excellent solution” for a miner new to collision avoidance systems and looking to stay a step ahead of inevitable related safety regulations, the company said.

OmniPro uses award-winning Visual Artificial Intelligence to detect and alert for people, vehicles and stop signs. (Photo: Matrix Team)

OmniPro “uses Visual Artificial Intelligence (VAI) to detect people and pre-selected objects, such as vehicles and stop signs, within a mobile equipment unit’s projected travel path and alerts the operator of their presence,” said Chris Adkins, mining manager, Matrix Team. “Matrix received the NIOSH 2020 Mine Safety and Health Technology Innovations Award for OmniPro’s VAI technology.”

The system is designed for small- to medium-sized mobile machines, and is currently being tested on large ones. It “operates as an independent warning system and does not require location devices or equipment tags,” Adkins said.

“OmniPro operates as a single-, dual- or three-camera system for a wider coverage area with each camera having a 120° field of view,” he said. “Its customizable zones within the field of view can be set to match the operating environment.”

The system “records and stores breach incidents with time-stamped photos and, in two-camera systems, auto-switches to only monitor the vehicle’s direction of travel to reduce nuisance warnings,” said Don Knuckles, domestic industrial sales, Matrix Team.

The plug-and-play design allows for easy installation. “A stand-alone system, it can be used with almost any OEM equipment,” Knuckles said. “OmniPro can help reduce heavy-to-light vehicle interaction, which is a major issue in surface mines. Additionally, through its alerts, it teaches operators and pedestrians safe habits.”

Safety managers can use it “to determine areas most likely to have close calls and to identify training opportunities,” he said. “It can benefit ‘near-miss initiatives’ by providing data that can be reviewed and acted upon.

The system has garnered positive feedback from customers.

OmniPro requires no preexisting infrastructure and is an ‘excellent solution’ for a miner new to collision avoidance systems, Matrix Team says. (Photo: Matrix Team)

For example, it was installed two years ago at a coal preparation plant facility in West Virginia to prevent loader-to-vehicle collisions. “After an accident there resulting in $25,000 in damage to the radiator of a coal truck by a front-end loader, the facility wanted a collision avoidance system that would help prevent future incidents,” Adkins said.

“In the two years since OmniPro has been installed, there have been no collisions,” he said. “The company is very pleased with the results.”

The system arose from market research related to the development of the highly popular IntelliZone proximity detection system, released in 2009 to the underground coal market.

“Seeing the need in the marketplace for a product like OmniPro, Matrix has been working to develop the system for several years,” Knuckles said. “We wanted to develop a less expensive solution than those found in the explosive mining environment using the most advanced technology available.”

The result is “a cost-effective, independent collision avoidance system for every size of surface mine,” he said. “It has been in trials for some time, but was officially introduced into the mining market at MINExpo 2021.”

The system requires no preexisting or specialized infrastructure. “The only thing needed is a willingness to be safe,” Adkins said.

The release “further emphasizes our commitment to improving the lives of miners,” he said, “and assisting operators in having a productive and safe work environment.”

CAS 10 features a new 5-in. LCD screen and a new smart antenna that supports GPS, RF, Wi-Fi, LTE, and Ultra-Wide Band Time-of-Flight technology. (Image: Hexagon)

Hexagon Launches CAS 10

Hexagon announced HxGN MineProtect Collision Avoidance System 10 (CAS 10), the latest version of the popular system used at mines around the world to help improve safety, manage fleets and digitize operations. “CAS was already the market-leader among collision avoidance systems,” said Barbara Hirtz, product manager, Hexagon’s Mining division. “CAS 10 advances the technology by consolidating even more functionality into fewer parts.”

CAS is currently used in more than 50,000 vehicles at mines worldwide. “It protects drivers and equipment with 360° operator awareness via a non-intrusive cabin display unit for vehicles, assets and operators in open-pit mines,” Hirtz said. It also “will integrate systems for operator alertness, personal protection, radars and vehicle intervention.”

CAS 10 features two major hardware upgrades, a new smart antenna and a new 5-in. LCD screen.

“The smart antenna embodies sensor integration,” Hirtz said.

“GPS, RF, Wi-Fi, LTE, Ultra-Wide Band Time-of-Flight technology are all housed in a single device, reflecting Hexagon’s Power of One approach,” she said. “This allows multiple Hexagon solutions to share one antenna, reducing the cost of ownership while facilitating maintenance.”

The antenna allows positioning data to be shared with other solutions. “At many mines, you’ll see several GNSS antennas serving almost the same functionality mounted on vehicles,” Hirtz said. “Hexagon’s smart antenna shares this data with other devices, consolidating the hardware to be installed.”

For example, the smart antenna “data is shared by our fleet management solution, MineProtect Operator Alertness System (OAS) and CAS 10, thus reducing the overall cost of ownership.”

The CAS 10 LCD screen has “touch capability, high brightness, high-volume speakers made for the mining environment, and a completely new UI/UX design focusing on operator experience,” Hirtz said. “It’s much easier to install and use.” It will “help the operator make better decisions in traffic.”

CAS 10 emerges now as the apex of a decade-long evolutionary process. It harnesses major advances in communication technology, sensors and positioning technology from the automotive and electronics industry.

“While the older generation of CAS is still fully functional, newer and faster technologies are now available that the older generation cannot support,” Hirtz said.

“CAS 10 is part of the Power of One, the culmination of Hexagon’s push to empower digital transformation by consolidating and connecting sensors and software, infield apps and cloudware,” she said. “So, one multifunctional smart antenna not only incorporates CAS, but also supports systems for operator alertness, fleet management and operator assist, among others.”

The development of CAS 10 was driven by customer feedback. “The consensus among CAS users was that reducing the number of hardware components would make installation and maintenance easier and improve the ordering and supply chain process.”

For example, the system features the latest generation of GPS modules, “which not only improves safety capabilities but enhances operator adoption,” Hirtz said. “We focused on user interactions and how vehicle operators absorb information from an onboard safety device to increase situational awareness and safety.”

CAS 10 and the MineProtect portfolio can support the digitization process at most surface mines, regardless of their operational maturity, Hexagon reported. The primary benefit offered is a step-change in worksite safety, Hirtz said. That step-change can be reached incrementally.

“OAS can combat fatigue and fatigue-related events,” Hirtz said. “Two-thirds of all accidents in mines are either due to blind spots or operator fatigue, hence the success of OAS and CAS.”

The next level can be attained through Personal Alert and radars, which “features vehicle-to-people and vehicle-to-object detection.” In combination with CAS and OAS “this offers an unparalleled level of safety,” Hirtz said.

“CAS 10 will be the ideal platform to help mines to introduce autonomous solutions by safely assisting the interactions between human drivers and autonomous vehicles.”

In its simplest form, however, CAS 10 can be a standalone solution, and therefore requires minimal preexisting infrastructure.

It can “connect to a web-based reporting and analytics platform that adds a powerful layer of safety to MineProtect,” Hirtz said. “It monitors and controls critical risk events by connecting data sources via live dashboards, visualizing all aspects of CAS.” For that, and for remote maintenance and firmware upgrades, Wi-Fi or LTE is required.

And for CAS 10 to deliver to its fullest potential, other MineProtect solutions are required.

“Our customers understand that to take zero harm seriously, they also need an enterprise solution to transform safety data into actionable intelligence, backed by a proven change management methodology to ensure a meaningful safety culture prevails,” Hirtz said.

“The daily dangers faced by miners are too numerous and too varied to be addressed by point solutions and multiple vendors,” she said. “Poor visibility, blind spots, fatigue, distraction and slope instability can only be mitigated by a comprehensive safety response, combining technology, change management and a commitment to zero-harm culture.”

CAS 10 ensures that commitment doesn’t sacrifice productivity. “It is the most valuable investment a mine can make,” Hirtz said.

It allows existing Hexagon customers to adopt with “reduced deployment and training time, reduced supply chain complexity and increased operator adoption,” Hirtz said. “This is a landmark enabler for next-generation autonomy, offering mines a uniquely intelligent approach. Most importantly, everyone gets home safely.”

Cat’s Command for Hauling

Caterpillar reported its LiDAR system makes Command for hauling the top autonomous haulage system at, among other things, collision avoidance.

“LiDAR is the best perception system out there,” said Jagath Samaraweera, consultant for Cat MineStar Command for hauling. “It lets our trucks run faster than anyone else’s, and that means they’re more productive and more efficient.”

The original LiDAR technology that was the basis for the current solution was designed for civilian applications. Caterpillar acquired it and spent a decade developing, hardening, testing and perfecting it for mining applications.

“When we bought it, the trucks would stop nearly 200 times a day for dust,” Samaraweera said. “Now our machine learning has gotten so good they don’t even slow down for dust anymore.” In fact, the elements rarely impede its operation. “They run in the rain, fog, snow. They run at night,” he said.

“They’ll stop to let kangaroos cross the road,” Samaraweera said. “I’ve even seen one on a site in Canada follow a family of moose down the road at a safe speed until they got out of the way.”

LiDAR helps Command trucks operate where manned trucks cannot. “Usually truck operators have to stay out of the blast radius for safety,” he said.

“With no operators, Command trucks can operate through the blast radius if the customer chooses, which allows them to be more productive,” Samaraweera said. “Keeping operators out of the cab is obviously good, but LiDAR is a big part of what makes it safe for Command trucks to operate around other machines and people, too.”

Cat MineStar Command for hauling uses LiDAR technology that evolved from a solution on the civilian market. It is the ‘best perception system out there,’ Caterpillar reports. (Image: Caterpillar)

LiDAR provides machine vision for the trucks. It fires 64 Class 1 lasers more than 1 million times per second, creating a detailed point cloud showing where the lasers encounter solid objects, Caterpillar reported.

“The device’s cylinder rotates at 600 rpm, offering wide coverage of the truck’s path to ensure that nothing enters the area without the truck detecting it in time to respond appropriately,” Cat said. “This could mean slowing down, stopping, honking the horn or any other action necessary to avoid a hazardous situation.”

So far, Command has a near-perfect batting average for collision avoidance and generalized safety. “To date, Cat autonomous trucks have hauled more than 4 billion metric tons of material without a single lost-time injury,” Cat said.

Command trucks have “traveled more than 147 million kilometers using this system,” Samaraweera said. “We’re always looking at new ways to improve it.”

Recently, Command was deployed to a Canadian oil sands operation. Driving snow, freezing temperatures, and soft roads are the norm for much of the year. Command was configured to detect ruts in the soft, snowy haul roads and to drive over them, as opposed to stopping for them, Cat reported.

It was also programmed to “distinguish between objects and the speed with which it can respond” to them, Cat said. The result was improved speed, safety and productivity.

That sort of success bodes well for the future of Command.

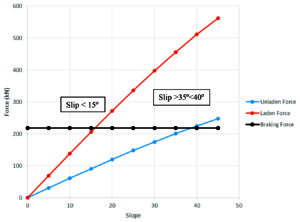

Determining the force of loaded and unloaded trucks on a downhill slope can pinpoint the gradient at which wheel-locking interventions could cause slippage. (Image: Kaelo, Olehile; et al.)

Study: Automated Intervention for Trucks on Downhill Slope Could Cause Accident

A study1 by university researchers from South Africa and Zimbabwe found that a collision avoidance system on 40-mt haul trucks could cause “accidents” if it intervenes with wheel-locking stops on mine roads with a 15° or greater downhill grade.

Fully loaded trucks descending such slopes would likely skid forward, perhaps uncontrollably, after an attempted sudden stop, the study found.

The study looked at the engine and braking specifications of Bell 40E articulated trucks used at the Canyon coal mine in Mpumalanga, South Africa. It applied equations for static friction forces to determine the downhill grade where the momentum of a Bell 40E exceeds the force of a wheel-locking emergency-intervention stop automatically triggered by a collision avoidance system.

On the trucks, the service brake gives a maximum force of 488 kN. The emergency brake gives 218 kN. The truck also has an engine brake.

When the collision avoidance system detects what it thinks is an impending crash, it intervenes and slams on the emergency brake.

“The braking system is tested and has been certified to work, in the sense of locking the wheels successfully,” the study said. “The tires behave according to the environment they are in” and in some scenarios can “slip, even if the wheels are locked.”

An unloaded Bell 40E weighs roughly 35.7 mt. A loaded one weighs 81 mt. The study took the specifications of the trucks, at the two weights, and a range of slopes and plugged them into “equations of static friction” that make up, in part, Coulomb’s law.

“When the sum of the normal forces was zero, the frictional force was equal to the applied force, and the friction factor was 1, and/or the frictional force was greater than the applied or the normal force, there was no apparent motion,” the study said.

Further, when “the applied force or sum of forces is equal to the frictional force, and the friction factor is 1, the truck is just-before instantaneous motion,” it said. At “the point where the applied force or the normal force is greater than the frictional force,” the truck can “slip and enter into a field of vehicle dynamics, where an accident might occur.”

The emergency braking system gives 218 kN force. When the applied force goes beyond 218 kN, the truck goes into “dynamic mode and starts moving uncontrollably,” the study said. “For the loaded truck, the slip is slightly below 15°, and for an empty truck the slip is between 35° and 40°.”

The study said “ideally the maximum slope of a mine (road) is about 12°.” Mines, in reality, sometimes have roads with grades of up to 45°, it said. The findings of the study suggest that for a mine using Bell 40Es, slopes of “more than 35° are not just reckless but a danger to the people and machines.”

For loaded trucks at the Canyon mine, the collision avoidance system should be programmed to do emergency intervention wheel-locking stops on roads with grades of less than 15°, it said.

1 Kaelo, Olehile; et al. (2020) Collision Aovidance Technology: The use of Fourth Industrial Revolution (4IR) for Safe Mining. Published and hosted by the IEOM Society International.