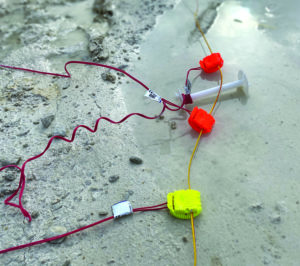

The new E*STAR Connectors from Austin Powder have an all-weather resistant seal, ensuring E*STAR detonators will function as intended even in low temperatures or precipitation. Built with field conditions in mind, E*STAR Connectors are easy to handle while wearing gloves because of the grip provided by anti-slip contours and the robust flip-top hinge. A blaster can open the connector using just one thumb, yet once closed, the connector is sealed and secured from dirt, debris and moisture ingress.

The new E*STAR Connectors from Austin Powder have an all-weather resistant seal, ensuring E*STAR detonators will function as intended even in low temperatures or precipitation. Built with field conditions in mind, E*STAR Connectors are easy to handle while wearing gloves because of the grip provided by anti-slip contours and the robust flip-top hinge. A blaster can open the connector using just one thumb, yet once closed, the connector is sealed and secured from dirt, debris and moisture ingress.

So much innovation is packed into these small devices to ensure the highest standard of usability, reliability and safety. Duplex bus line wire eliminates the need to split wires when making a connection, thus saving time and decreasing the chance for wire damage during splicing. With E*STAR, the connection is made by simply placing the duplex wire into the connector (in any polarity) and snapping the lid shut.

“E*STAR connectors are leading the industry with their new innovative ‘double connect’ capability on both the leg wire and duplex wire. The double connect capability allows for eight points of contact on the detonator leg wires and eight contact points on the bus lines. The new E*STAR connector effectively ensures a 100% reliable connection of all wires within the connector, at all times,” said Campbell Robertson, global manager of Electronic Initiation Systems at Austin Powder. “Blasters can also perform through connector testing without reopening the connector, streamlining the testing procedure.”

Also, the new connectors make both detonator-to-logger and detonator-to-branch connections faster and more reliable. Wire type and length are identifiable at a glance because of standardized color-coding. The connector’s back is flat with ample surface area so the delay time or other pertinent information can be noted.