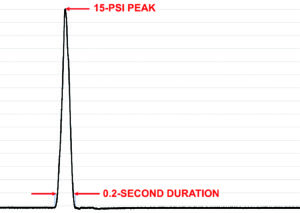

The overpressure profile developed for relief valve explosion survivability testing.

NIOSH researchers develop methods to assess relief-valve explosion survivability

by john homer

Three mine disasters that led to Congress passing the Mine Improvement and New Emergency Response (MINER) Act occurred within the first five months of 2006. Arguably, this legislation brought about some of the most significant changes to underground coal mine safety and emergency response since the Federal Mine Safety and Health Act of 1977. The MINER Act was responsible for policy and rulemaking to improve preparedness and response efforts for mine disaster events. This comprehensive piece of legislation addressed key elements for disaster preparedness and response, including communications and tracking, emergency response plans, mine rescue teams, and underground refuge alternatives. The act set forth regulatory changes to be enforced by the Mine Safety and Health Administration (MSHA) and critical research to be conducted by the National Institute for Occupational Safety and Health (NIOSH).

Refuge alternatives are intended to provide shelter from life-threatening conditions imposed on miners by fires and explosions in underground coal mines. While seeking shelter in underground mines is still considered secondary to escape, refuge alternatives and their components must be able to withstand human-survivable events prior to their deployment.

A major focal point of NIOSH research is to ensure that refuge alternatives and their components remain functional after survivable explosion events that occur in underground coal mines. As part of addressing technical issues surrounding refuge alternatives, the NIOSH Pittsburgh Mining Research Division, in cooperation with the MSHA Approval and Certification Center, has developed test methods and evaluated relief valves for their ability to withstand overpressure generated during a survivable mine explosion.

Federal Requirements

Following passage of the MINER Act, MSHA published its final rule in December 2008 mandating provisional access to refuge alternatives in underground coal mines, including requirements for testing and approvals, ensuring their availability, and comprehensive training for miners. MSHA regulations, specified in Title 30 under the Code of Federal Regulations (30 CFR), require refuge alternatives to be capable of surviving 15 pounds per square inch (psi) of overpressure for 0.2 seconds prior to their deployment. These criteria were adopted with respect to test data collected during explosion research conducted at the former NIOSH Lake Lynn Laboratory to establish the shape of the curve, while the pressure aspect was based on military data for blast survivability. Both were necessary, since the possibility for human survival in terms of an underground coal mine explosion is not solely determined by exposure to blast pressure, but also by the effects resulting from its propagation, such as flying objects and debris. In terms of a design requirement, the specified 15-psi, 0.2-second overpressure is justified in regard to human survival, as explosions of this magnitude result in almost certain mortality.

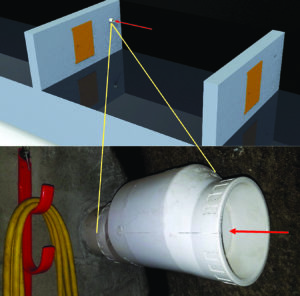

Enclosure developed for refuge alternative relief valve testing.

Relief Valves

Relief valves are a critical component of the ventilation systems for built-in-place refuge alternatives. These valves prevent contamination from entering the structure, limit the buildup of pressure, and allow contaminated air to exit the refuge alternative. NIOSH has conducted research to determine if relief valve designs are capable of providing adequate airflow for maintaining atmospheres that are safe for breathing, free of smoke and harmful gases, and supplying adequate levels of oxygen.

Various issues surrounding pressure relief have also been addressed by NIOSH research. Ventilation systems for refuge alternatives must provide sufficient airflow while ensuring that internal pressure does not exceed 0.18 psi above the mine atmosphere. Here, the concern is that pressure within a refuge alternative must be limited in order to ensure the comfort of its occupants, and that basic functions, such as opening and closing the door, can be performed to allow for safe entrance and egress. Despite these efforts, one critical question remains: Can relief valves survive an explosion event? If not, a failed valve can prevent the flow of air and result in a buildup of pressure and contamination. In addition, a failed valve may allow contaminated air to enter the structure from the outside mine environment. To address this concern, NIOSH approached the question of relief-valve explosion survivability by developing their own test methods in cooperation with the MSHA Approval and Certification Center (A&CC).

A built-in-place refuge alternative depicting relief valve outflow.

Explosion Testing

NIOSH researchers have developed a framework for subjecting refuge alternative relief valves to targeted overpressure profiles using an enclosure designed for intrinsic safety. Using this approach, concentrations of methane and air can be mixed within the enclosure and ignited to successfully generate controlled explosion events. Peak pressure and duration can be adjusted to examine the effects of exposure to overpressure, including the 15-psi, 0.2-second duration design pressure specified in 30 CFR, as well as additional profiles. The test methods developed by NIOSH in cooperation with the MSHA A&CC include the use of a large enclosure, approximately 300 liters in volume, for producing overpressure durations in the range of 0.8 seconds, and a significantly smaller enclosure, of about 35 liters, for producing shorter durations in the target range of 0.2 seconds.

Peak overpressure is controlled using a 3-in.-diameter ball valve. By adjusting the valve’s handle or ball angle, the valve opening is set to throttle the flow of combustion gases, thereby regulating the amount of overpressure generated within the vessel. A plastic cap is required to contain the methane gas mixture within the enclosure prior to its ignition. Once the ignition occurs, the cap is forced from the ball valve opening by a rise in pressure that occurs within the enclosure.

Although controlling the amount of peak overpressure is a significant challenge, this is achieved using a precisely controlled, uniform and consistent mixture of gas within the enclosure. Another key requirement for achieving the best control is tied to the location of the ignition source. Improper placement of the ignition source can result in violent combustion as well as inconsistent pressure generation. NIOSH researchers were able to overcome these challenging aspects with assistance provided by the MSHA A&CC. Their facility in Triadelphia, West Virginia, is equipped with an explosion test gallery and is staffed by engineers with expertise in explosion testing intrinsically safe enclosures approved for use in U.S. underground coal mines. This resource was paramount to efficiently develop this methodology and reliably achieve the desired characteristics of overpressure by way of using a controlled explosion event.

MSHA Approval and Certification Center explosion test gallery.

Results

In cooperation with the MSHA A&CC, NIOSH researchers have successfully developed a framework to examine refuge alternative relief valve response to explosion overpressure, including the MSHA-specified overpressure of 15 psi for 0.2 seconds. The developed approach affords the ability to test the integrity of relief valves for withstanding overpressure, representative of an actual coal mine explosion while being generated using a controlled explosion event. Using this method, relief valves can be successfully designed and tested for withstanding a survivable explosion in an underground coal mine. This method provides a way to physically test a valve’s ability to withstand overpressure from a mine explosion and to maintain intended performance in terms of airflow and pressure relief.

To date, seven relief valve designs have been assessed using a 15-psi, 0.8-second overpressure profile afforded by use of the large enclosure. Plans for conducting relief valve assessments using the smaller enclosure have been postponed indefinitely by restrictions imposed as a result of the novel coronavirus pandemic in 2020. Although there are no immediate plans to continue this research, relief valve assessments should be conducted using the smaller enclosure to subject them to overpressures consistent with the regulatory-specified duration of 0.2 seconds.

Ball valve throttling combustion gases for overpressure regulation.

This work is applicable to testing and improving relief valve designs for underground refuge alternatives used in coal mines. The developed methods could also be scaled up to examine other components, such as doors and stoppings, for their ability to survive explosion events.

John Homer is a lead general engineer for the Mine Systems Safety Branch of the NIOSH Pittsburgh Mining Research Division. He can be contacted at JHomer@cdc.gov. For more information on NIOSH refuge alternative research, visit www.cdc.gov/niosh/mining/researchprogram/projects/project_RefugeAlternatives.html.

Disclaimer

The findings and conclusions in this article are those of the author and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of any company or product does not constitute endorsement by NIOSH.