The bauma trade fair will return to Munich, Germany, in October 2022. (Photo: bauma)

Quality German solutions for digitalization, electrification and automation in mining are driving export sales, reports Klaus Stöckmann, VDMA Mining’s deputy managing director

This year (2022) is a bauma year. With an area of 614,000 m2 and 627,603 visitors in 2019, it continues to be the largest trade fair for construction and mining machinery globally, and an important platform to present latest innovations in technology and processes.

Ten years ago, we were dreaming of self-monitoring systems, high availability, better productivity and competitiveness as key factors in Industry 4.0. The mining industry, against the backdrop of declining ore grades and increasing demand for raw materials, was looking for smarter solutions.

For the branch represented by VDMA Mining, the production of technology to mine the resources needed for a greener future — raw materials for buildings, infrastructure, computers, construction machines, vehicles, sensors, control and so on — is at the center of all efforts.

To answer this challenge, VDMA Mining members have drawn upon their decades of experience with inventive, innovative strength and channeled it into their offerings. Many of these we present to you today in the Best of Germany, and many more will be showcased at bauma in the fall.

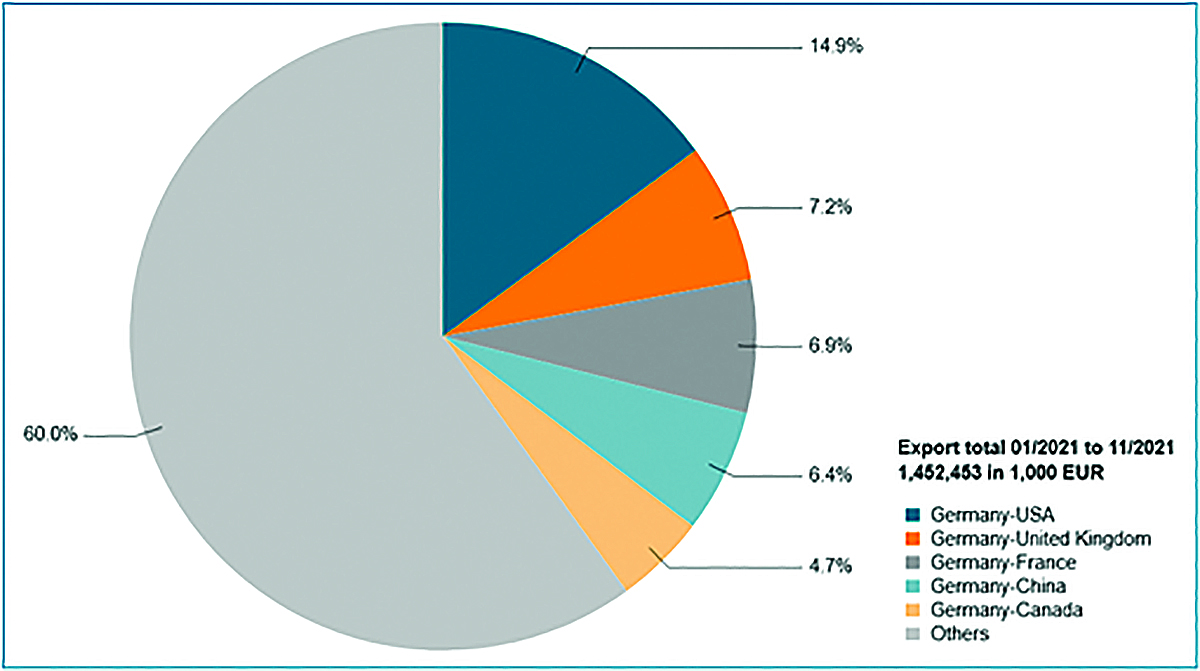

Export markets by size, January-November 2021. (Source: VDMA Mining)

Digitalization for ‘Green Mining’

In recent years, the topic of digitalization has gained enormous momentum and the adoption of digital solutions has accelerated. The options available for mechanical systems to effect radical changes are fairly limited. However, even the most ingenious information technology (IT) will get nowhere without the help of mechanics in the broadest sense. The torque must be transmitted, and the impulse converted into movement. Digitalization presents new, creative opportunities to effect these actions, and hence new business models.

The success of automation relies upon a platform that provides consistency of operation, performance and standards for information access. This is precisely what the VDMA Mining is focusing on today. We are working on connecting different types of machines, of different ages, both with each other and with higher-level control centers.

In various working groups consisting of equipment manufacturers, mining operators and academia, we are developing an OPC UA Companion Specification for Mining. These working groups determine which data from which machines are relevant for automated processes, develop definitions for the configuration of the interfaces and then jointly define the appropriate standards that ensure a reliable flow of information. Representatives from Canada, the U.S., Chile and Australia are also involved in this work. Finally, these specifications are published as IEC standards via standardization bodies and the OPC Foundation.

The first results are due to be published at bauma in Munich, Germany, in October. In addition, the participating companies will demonstrate how different machines and systems can communicate and operate autonomously in mining using the new standards. All of this serves to make mining processes safer, more effective and less polluting to the environment. We hope that in October, the COVID-19 pandemic will no longer be impacting trade fairs across the globe, including those in Russia, Asia, Africa, North and Latin America.

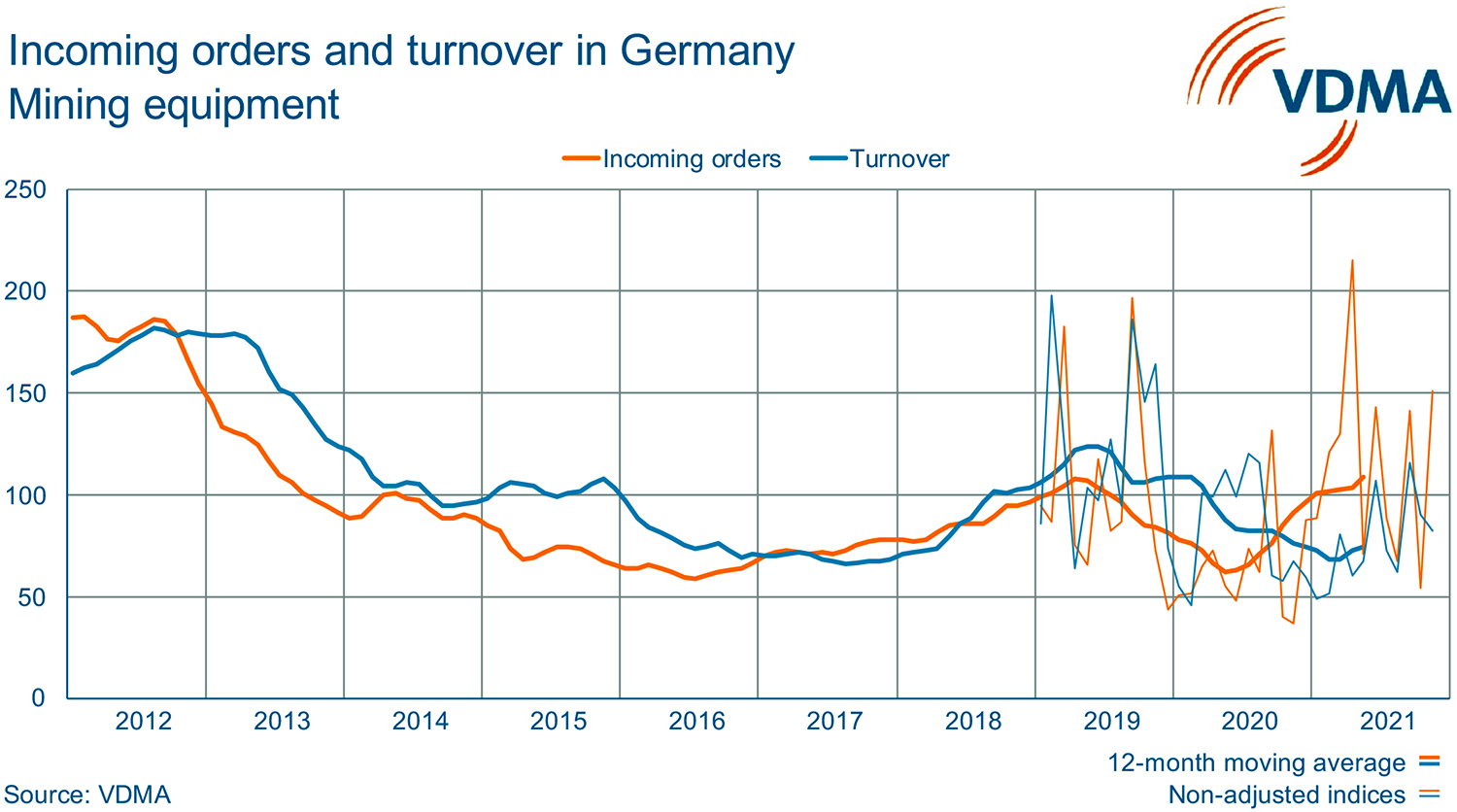

Incoming orders and turnover, 2012-2021. (Source: VDMA Mining)

Steady Growth Into 2022

Overall, German mining equipment, technology and services providers have weathered the disruptions from COVID-19 well. Following the initial shock, order intake has risen above the sales curve since Q4 2020.

Although exports declined overall in 2020 due to the impacts of COVID-19, 2021 delivered a stable result both in exports and turnover. Compared with 2019 — pre-COVID-19 — the U.S. is still the largest export market for German mining equipment

and technologies. The U.S. market does not pose an extraordinary challenge in contrast to China. The Asian country only imports technology that is not yet available locally in the desired quality, and this reduces export figures for mining equipment manufacturers with production sites in Germany. Remarkably, the U.K. is the second biggest export market, followed by France. This is likely due to a large number of infrastructure projects with tunnel construction sites in both countries.

COVID-19 notwithstanding, global demand for machinery is generally good again. For many raw materials, such as metals or coal, the rapid increase in demand can hardly be met. As a result, many commodity prices are reaching new highs. In this environment, global mining companies have profited, especially with copper, iron ore, coal and gold. This makes now a good time for investments in new ideas for the extraction and processing of raw materials, and offers for further automation, digitalization and zero-emission innovations are sought after.

A look at the global mining industry shows a clear focus on climate and environmentally friendly processes as well as digitalization. The pressure for this is coming from the financial sector. There are many ways to achieve these goals, from alternative drives for the equipment to autonomous operation and the necessary communication and data technology.

The stellar reputation of German mining equipment, technology and service companies is founded on sophisticated technologies along with excellent customer service, whether delivered in person or online. The long-standing business relationships these companies have built with their global customers have been maintained, even through difficult times.

You can rely on German technology providers, whatever the weather.