TAKRAF has implemented an initiative for the collection of operational data to create a ‘data lake’ that can be used to generate machine condition insights.

From cloud computing to digital twins and smart glasses, Tenova TAKRAF is harnessing IIoT-enabled technologies to provide solutions for 21st century mines. Gunnar Zergiebel, head of electrical and instrumentation — Material Handling Dept, explains

In recent years, Industry 4.0 has evolved from an abstract marketing term to a real-life beneficial use concept. Often mentioned in conjunction with terms like the Industrial Internet of Things (IIoT) or cyber-physical systems, it describes the continuous development towards a fourth industrial revolution — the digitalization of almost all areas of our life. Today, the use of automation, real time processing of huge amounts of data, artificial intelligence (AI), robotics, pay-per-use business models or cloud computing, to mention just a few things, come together to enable a more efficient and effective economy.

TAKRAF is a highly specialized supplier of machines and services in the fields of mining, materials handling and minerals processing. As such, the company boasts a large base of installed machines that daily generate valuable data from which information regarding optimization of design, operation and maintenance or even troubleshooting can be gained.

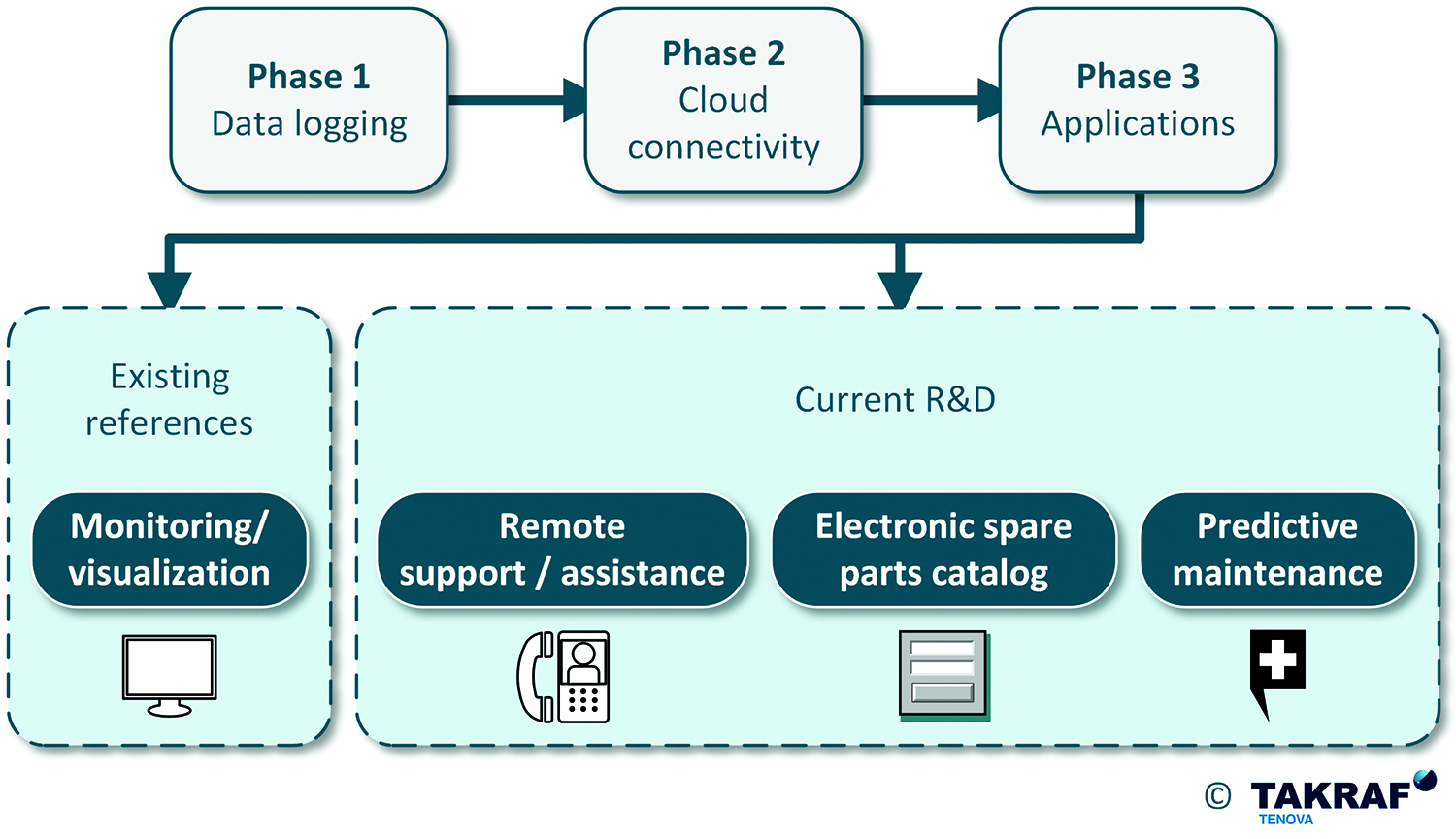

Leveraging this opportunity, TAKRAF implemented an initiative for the collection of operational data for select representative machines and/or key components. This so created ‘data lake’ is being used for the development of concepts to generate insights regarding machine condition and machine KPIs that can be of great value to customers and various internal departments.

Within this process, TAKRAF learnt that, even though data is the basis for almost all IIoT strategies, there is a significant difference between data and information. The most important and possibly most difficult step is generating useful information from collected operational data. With this in mind, TAKRAF developed a proprietary cloud environment, based upon the Microsoft Azure platform. This environment provides the opportunity to transfer and store data from “edge computers” at TAKRAF machines and process them in a cloud environment with a wide variety of available technologies.

As a side benefit, such data sets within the cloud can be easily exchanged with systems that may already exist within a mining operation’s IT infrastructure. One pilot-application that was developed is a web-based application that shows basic KPIs and machine condition in a simplified and easy to understand manner on dashboards. This tool, called WIDE, can be used by clients and/or by internal engineers alike with a view to combining operational experience with the company’s deep knowledge of the system’s design. The possibilities to thus develop further applications that suit the needs of the company’s clients are virtually unlimited.

Another topic on TAKRAF’s R&D roadmap is dealing with so-called digital twins of machines. Since significant effort is invested in the design of a machine using digital 3D design tools, it makes sense to reuse this engineering data through the entire lifecycle of a machine. There are a variety of promising tools available today that link design data with live data coming from a machine’s control systems, or with asset management data such as documentation or maintenance activities into one common plant model.

A further key outcome from the company’s R&D activities include remote support solutions employing “smart glasses.” Such tools are relatively easy to implement and readily available. These glasses allow commissioning engineers or a customer’s maintenance staff on site to connect to TAKRAF experts in the office. Specific problems can thus be quickly and effectively solved, together with the avoidance of long trips and associated travel costs. For proof of concept, TAKRAF availed itself of a solution from Epson using their Moverio BT-2200 smart glasses.

TAKRAF develops a proprietary cloud environment, based upon the Microsoft Azure platform for use in various processes, including R&D.

An interesting “smart tool,” which the company successfully presented at the 2019 bauma mining exhibition in Munich (Germany) is based on Schneider Electric’s Augmented Operator Advisor. This software, which runs on a tablet, determines its positioning in the field based upon image recognition of the various parts around the user. Based upon this recognition, various points of interest can be defined together with context sensitive information such as manuals and maintenance procedures — live data can also be made available to the user.

Lastly, an important item on TAKRAF’s R&D agenda is the implementation of electronic spare parts catalogues, which aim to simplify and improve the TAKRAF client experience. Linking predictive maintenance tools into such electronic spare parts offerings will enable clients to conduct proactive maintenance in an effective and cost-efficient manner, thus increasing the availability of the company’s equipment.

TAKRAF has recognized the enormous benefits that IIoT technologies can provide to both customers and internal processes alike.

Architecture of Data Acquisition and Cloud-connection Tools

Based upon current IIoT technologies available, TAKRAF equipped a select sample of machines with remote data logging systems as a part of the company’s aforementioned R&D initiatives.

One of the first successfully integrated systems is working in a high-capacity spreader and tripper car for a large overburden-handling project in Southeast Asia. This system was designed and is based upon hardware and software components supplied by iba AG, a specialist for data logging and analysis. A machine connector reads defined data from the Profibus DP of the machine control system without jeopardizing its security and/or integrity and writes those to the iba PDA server. On this server, data is locally stored and analyzed, e.g., for automatically generated reports. Recorded data is then sent to company headquarters simultaneously or in batches.

Selected data can be transferred from the iba server to the Tenova cloud environment, which is hosted on the Microsoft Azure platform. Communication is based upon OPC, with the server hosted in the field and the cloud acting as a client. Several API have access to this stored data providing the end user with services such as access to an online monitoring system.

Logged data include status and error words, temperatures, process parameters such as conveying capacity, environmental conditions and much more. Presentation of recorded information is based upon the proprietary WIDE dashboards mentioned previously.

Further to the above examples and advantages offered by the IIoT, it should be remembered that these developments are more of a journey that has just started, rather than being a completely defined approach to a well-defined destination. TAKRAF is ready and willing to pursue these opportunities together with its clients.