THE LATEST TECHNOLOGY – AND SOME LONG-RECOGNIZED MAINSTAYS – FOR EVERY OPERATION’S KEY LOCATIONS

BY Donna Schmidt, Field Editor

|

| A mine’s initial support plan before revision. |

Of all the underground occupations, roof bolting is one of the most dangerous. The job is less routine than operating a continuous miner or a shuttle car. The miners are exposed to unsupported top, albeit at a distance, and they have to work with a number of components, including the drilling machine (roof bolter), drill steels and bits, resin cartridges, the bolts themselves and the bearing plates. When they encounter difficult conditions, such as poor roof geology or water (or both), the situation becomes risky for them and everyone else traveling under those supports. In addition to being an arduous task, roof bolting is often considered the slow point for continuous mining operations.

Several of the suppliers who service this aspect of underground coal mining are looking at ways to improve safety as well as the performance of the ground control tools. Some changes include modifications to hardware as well as improvement for the tools and machines used to install these anchoring systems. While many of these improvements appear to be common sense approaches, the reality is that a substantial amount of R&D has been invested in these advancements.

At the end of the shift, the goal is to adequately support the top safely for the amount of time miners will be traveling beneath it. The object is to get it right the first time. These suppliers are working to make sure the miners reach those objectives.

Jennmar Invests in R&D

While a family company, Jennmar’s role in coal is global; it has developed and manufactured ground control products for more than 40 years. Its engineering staff has also been focusing strongly on R&D and has recently unveiled several new products to its line.

The first is the JM Cable Fully Grouted Cable Bolt (FGCB), which was developed by affiliate KMS (Keystone Mining Services) and Jennmar after compiling key customer input and extensive lab and field testing.

Using the FGCB, a standard cable bolt can be fully encapsulated during installation or post-installation with polyurethane, or PUR; when fully encapsulated, a cable bolt is better protected than a traditional bolt from corrosive elements potentially present in the mine roof, which could affect the bolt’s structural properties, especially over prolonged periods of time.

FGCB is available as a non-tensioned (FGNT) and INSTáL Tensionable Cable Bolt (CB) and (CC) models.

|

| A close-up view of polyurethane injection. |

“Although [it was] initially developed for corrosion protection, field trials demonstrated that the FGCB can act as a traditional PUR injectable bolt for strata stabilization,” said Dr. John C. Stankus, KMS president; KMS is the Jennmar arm that oversees the research and development of new products. “The FGCB has proven to be a very versatile roof support system due to its ability to control many different ground conditions, from increasing the lifespan of standard cable-bolt supports in long-term main entry systems to stopping the ingress of water and allowing access to previously unattainable reserves.”

It is ideal for use in areas where a cable support is needed, including fractured and laminated conditions, outby/inby and in old works. It also can be applied in belt entries and for belt rehabilitations, for intersection support, at intersections for pillar recovery, in longwall recovery and setup entries, and in longwall headgate entries.

Jennmar cited a case study with one of its U.S. customer mines where supplemental support was installed approximately nine months after its longwall headgate was developed.

The roof in the area of the mine consisted of a highly laminated sandstone with mica streaks, and during installation of supplemental support, mining-induced roof fractures were discovered up to 11 ft above the roof line.

The location and density of the fracture were verified with a video borescope.

“Fracture density was very high in the first 4 ft above the roof line with some test holes showing six fractures per foot of test hole,” Stankus said.

Polyurethane resin was specified to consolidate the highly fractured immediate roof and 0.7- × 120-in. grade 270 FGCBs were used to inject polyurethane.

|

| The Jennmar B-Rigid Truss. |

“This bolt length produced an injection zone to 6 ft above the roof line when used with a standard 1.25- × 48-in. resin cartridge for anchorage,” Stankus said, adding that a single cable was installed approximately every 8 ft near the center of the entry and polyurethane was then used in conjunction with the previously installed supplemental support.

After the installation of the supplemental supports, polyurethane was injected into the FGCB cables and allowed to migrate into the roof; the movement was evaluated with a video scope and by day lighting of the polyurethane in adjacent bolt holes.

“With these methods, polyurethane was found to migrate in an approximate 10 ft radius around the bolt,” Stankus said. “In this case, the FGCB was used as a cost-effective and efficient method for consolidation of the immediate roof [and] the installed cost of the FGCB was approximately 75% of a traditional inflatable packer polyurethane injection system.”

Jennmar’s channel, mats, beams and mesh, including the popular T-Channels, the PH Roof/Rib Safety Channel, and Roof Mats, each have their own ideal uses underground for various conditions.

T-Channels, seven-gauge channels with a tensile strength of 60,000 psi, offer increased strength and safety versus roof mats, and can be installed with ease in regular bolting cycles. They are available in 8-ft to 20-ft sections and other lengths as needed for specific situations.

Gauges for T-Channels, which are used with advanced channel plates, range from 12 gauge to 5/16 in., with a tensile strength of 36,000 to 80,000 psi.

The PH Roof/Rib Safety Channel is designed for the control of roof and rib sloughage and to control “cutter” roof and add to the performance of wire mesh. It also can aid in preventing accidents due to rib sloughage.

The Roof/Rib Safety Channel is available from 12-gauge to 5/16-in. gauge, with a tensile strength of 38,000 psi to 80,000 psi. It, too, can help prevent accidents caused by rib/rolls and can also enhance the beaming effect of a mine and also offer resistance to roof sag and sloughage of the mine rib.

Jennmar roof mats can used for surface control to help prevent deterioration of the roof. The mats have been designed in lengths from 54 to 240 in. and come in variable widths from 4.5 to 10.5 in. In 12-, 14- and 16-guage offerings, the mats are hot rolled, cold rolled and galvanized and can be manufactured with bolt holes to suit a specific mine’s plan.

Jennmar’s truss systems include the following options: BYTM All-Thread Bar, BYTM Cable Truss, JMS Cable Truss, JMM Cable Truss and B-Rigid Truss. All have been designed to control specific conditions and all negate the need for the costs of cribbing and associated labor.

The company’s new addition, the J-SANDY Yieldable Prop, is lightweight, high capacity, and can be used in numerous underground applications including tailgate and bleeder support, cross-cut and intersection stabilization, belt line and headgate entry support, and longwall shield recoveries. It can provide 2 to 3 ft of height adjustment and can yield up to 8 in. Optional yielding devices on the J-SANDY include a yieldable dish, Piranha plate and mini-mat.

Finally, a new improvement to the time tested INSTáL point-anchor, resin assisted bolt system is the new TT Anti-Friction Washer. This new double galvanized washer replaces plastic friction washers and increases bolt installed tension by 20–25%, thus enhancing the roof beaming effect and roof stabilization.

|

| The mine’s revised support plan with the aid of Jennmar. |

Fletcher Improves Ergonomics

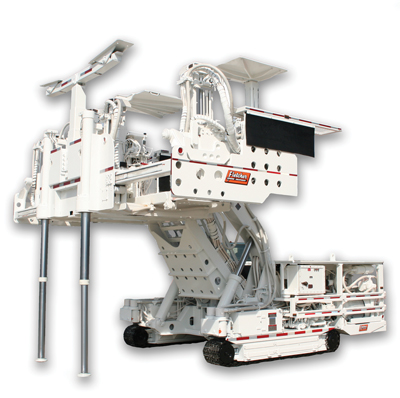

Complementing the ever-changing face of roof bolt technology is the bolting equipment sector, and one manufacturer answering that demand is W.Va.-based J.H. Fletcher. A pioneer in ground control known industry-wide for an attention to detail and flexibility of its line for varied mining conditions, Fletcher has cited the continued growth of its reliable standby WT-DDR and its newly introduced four-head and three-head bolters as the wave of the future.

According to company Domestic Sales Vice President Ben Hardman, the DDR WT has continually gained attention and popularity throughout the 2000s.

“The industry surge to develop metallurgical grade coal seams throughout Appalachia was a key element in the improved designs on the low seam Fletcher DDR WT,” he

said. “Seam heights below 50 in. created opportunities for various improvements in the layout of the Fletcher DDR WT to accommodate men crawling through the chassis as well as material flow issues.”

The DDR WT’s walkthrough chassis was designed to have numerous configurations, and the look and function of the machine has seen continuous improvements over the years since its release.

First, the walkway deck thickness through the length of the chassis was reduced from 9 in. to 4 in., giving the operator 5 in. of additional head room, and then a powered retracting entrance ramp was incorporated at the rear of the chassis.

A later change to the DDR WT was an automated material handling system for loading bolts, resin and other supplies (assembled outside the mine in trays) onto the machine chassis, followed by the design of an operator platform back guard that included a “butt rest” to permit the operator to rest his legs.

The lower seam Fletcher DDR chassis has been improved over time, and a spreading of the chassis permitted a crawl-through in especially low conditions. One of the more recent amendments to the design was the development of rib access booms for all walkthrough models, which allow the operator to better position himself in rib and truss bolt installation.

| The WT DDR is designed for operation in low-seam coal applications under 96 in. |

Among Fletcher’s latest additions: two CHDDR-4, known more commonly as the four-head bolter, to a client in China this year. Another two are currently in production and will also be headed for a Chinese operation.

The Fletcher CHDDR-4 mast feed roof drill is run by two operators, each working two separate drill masts. Using operator slide-out platforms, operators can use controls to bolt the inside, outside and toward the rib.

Also, because the masts operate independently from each other, operators can perform separate tasks simultaneously and maximize their production time.

China is seeing success with the four-head unit, but Hardman noted that its two-head bolters and the developing three-head bolter are having more success in the U.S. The stateside position regarding those models is primarily due to the design of the four-head, which places all four operators on a single platform from which drilling is performed; however, with the three-head and two-head support independent operating booms, the designs allow more flexibility in uneven and more narrow conditions.

Fletcher, the reputation of which proceeds it thanks in part to its development of the automated temporary roof support system (ATRS), has been working on the ergonomic aspect of its equipment and developing custom products. As with many of its ideas, these designs come to fruition thanks to user feedback from across the industry.

For example, Hardman noted the development of material handling machines, common on the DDR and HDDR.

“The rear of the machine is specially designed to haul supplies necessary for roof and rib bolting,” he said. “One advantage to the storage system, called a ‘material handling system,’ is that it can provide the operator immediate access to large varieties of roof bolt plates, steel straps and steel screen or mesh to be installed in the roof to prevent falling of small rock and debris. Materials can be loaded onto separate trays and stored on the rear of the machine.”

The system uses a hydraulic winch and material pods to load the heavy materials to the machine’s rear and a mechanized screen tray can be maneuvered up, down, side-to-side or tilted to position screen sheets for installation.

|

| A view of the walkway in use underground. |

“With the material handling system, loading bolting materials by hand is eliminated [and] materials can be loaded onto trays by the vendor outside of the mine,” Hardman said. “The trays then may be taken underground by supply cars and then lifted to a proper location on the rear of the roof bolting machine by the material handling system. This promotes reduced occurrences of injuries associated with repetitive tasks such as lifting the roof bolting materials onto the machine.”

Complementing the material handling machine for Fletcher, ergonomically and otherwise, has been its rib access booms, which can handle bolts, resin and straps for an operator that would normally be a burden to manipulate during bolting of the rib.

Since inception, according to Fletcher officials, the booms have steadily become the standard in lifting boom applications.

“The success of the Rib Access HDDR boom in western U.S. applications is evident because they have become a standard feature,” Hardman said. “With low seam heights in the east and difficult mining conditions, the walk through DDR with non-lifting boom has become one of J.H. Fletcher’s top sellers.”

The CHDDR-4 operates in entry widths from 5.5 to 6.5 m, with an average working height range of 3 m to 5.5 m, and the WT DDR is designed for operation in low-seam coal applications under 96 in.

An example of the Fletcher WT-DDR’s place in the industry is the company’s road to the birth of its modern design.

The original idea for the “walkthrough” (WT) chassis for the roof bolter came from the mine foreman at the No. 37 mine in the U.S. Steel Lynch District in Harlan County, Ky.

“In 1983, the No. 37 mine was in early development, and the seam height averaged 10 ft (3.05 m). The coal ribs were extremely hazardous,” Hardman said, adding that Fletcher sales and engineering people worked closely with the Lynch District chief engineers to develop the WT design.

These WT machines were model DDR high-seam roof bolters, having the drilling booms arranged for “inside the booms” operator control positions. Elevating operator platforms were incorporated on each drill boom to raise the operators, with the drilling controls, for easy reach of the mine roof.

|

| Fletcher’s CHDDR-4, known more commonly as the four-head bolter. |

The “inside the booms” operators control position concept had been developed previously in 1978 for Bethlehem Energy, Ellsworth Division in southwest Pennsylvania.

The inside the booms control arrangement affords the operators protection from rib hazards by placing the boom structure between the hazard and operator. The limitations of these earlier machines were that the operators were required to walk between the roof bolters and rib to enter or leave the booms control position. However, the design was a significant safety advancement for the day.

“Hazardous ribs were and currently are prevalent in many coal mines,” he said. “Soon after the U.S Steel No. 37 mine bolters were installed, [the] model DDO WT arm-feed roof bolters with inside the boom controls were built for Westmoreland Coal in Virginia.”

Another design stemming from working in tandem with an operator was the first model HDDR WT roof bolter, which was built for the Monterey Coal No. 1 mine in Illinois in the mid-1980s.

Soon after, the sales of Fletcher HDDR WT and other models spread to the western states, Alabama and Kentucky.

The rest, as they say, is history. Since the early 1990s, wheel and crawler Fletcher HDDR WT have been sold in England, Australia, China, Norway, Canada, Mexico and South Africa. The Fletcher HDDR WT roof bolter is now widely used in South Africa, where the room-and-pillar mining method is the prevalent mining system.

|

| Obduro acid-proof coating. |

DSI Offers Corrosion-Resistant Products

DSI Mining produces bolting supplies globally for the underground sector in 95 countries. It prides itself on being a key supplier to the top 10 coal operations.

Among DSI’s newest technologies for the bolting sector for coal are the recently released Pizza Pan (Mine+Safe Draw Rock Shield) for strength and safety in roof and rib surface control needs.

With no corners to give out or bend, safety risks are significantly reduced for the miners and equipment, DSI said.

|

| The Mine+Safe Draw Rock Shield, also known as a Pizza Pan. |

DSI first sought to acquire the Pizza Pan, designed by Three Rivers, last year because of its strength and safety qualities.

Another product new to DSI’s line is Obduro Acid Proof coating. Designed to be entirely corrosive resistant, it has been successful in extending underground support life and even eliminating rehabilitation in the harshest environments.

The Obduro coating can protect almost all of the DSI products, from cable and rebar to its Omega Bolts and hardware.

As a point to the product’s capabilities, DSI cited its work with one operation that had to rehabilitate every 30 days.

“Bolts were coated and pull tested underground every 30-90 days while undergoing corrosion in this particular mine for 18 months without failure,” Engineering Director of North and South America Renn Oler said of its work at the western U.S. coalfields mine. “These mines have environments with continual acid renewable runoff at pHs of 1.8 at concentrations of 15%. The coated bolts were cored out and had no corrosion. “There were also no inclusions in the coating after achieving yield loads.”

|

| The newly introduced DSI Truss Eye. |

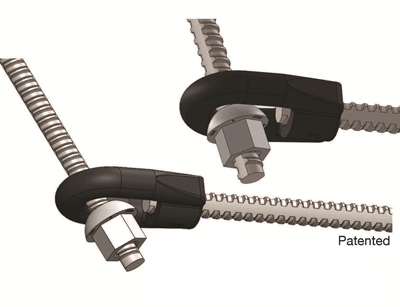

Another new addition to the DSI product line is the Threadbar Truss System, which offers structural rigidity and support in coal applications, and another soon to be introduced, the DSI Truss Eye.

“Truss systems are becoming more popular where a longwall headgate entry height is critical for a stageloader to pass as the longwall face advances,” said DSI Director of Rock Mechanics Dr. Jinsheng Chen. “It also provides support to fracturing and exceptionally soft ground to minimize roof sagging or failure.” The Truss Eye, which DSI said makes installations easier and less expensive, is also lighter with ergonimical advantages for the installer.

Finally, DSI’s development team is working to unveil the TensionLoc tensionable bar. With a design that is headed, versus the current industry standard tensionable rebar that uses a nut and crimp, this allows for faster installation times and a reduction in operational installation costs for mines. It also offers a lower profile extension, with only a square head protruding.