As Ben Franklin said, “When you’re finished changing, you’re finished.” The sentiment is particularly fitting to the cyclical, ever-transforming coal industry. With many periods of market waxing and waning over time, adaptation has become the norm — but resiliency has always been a constant.

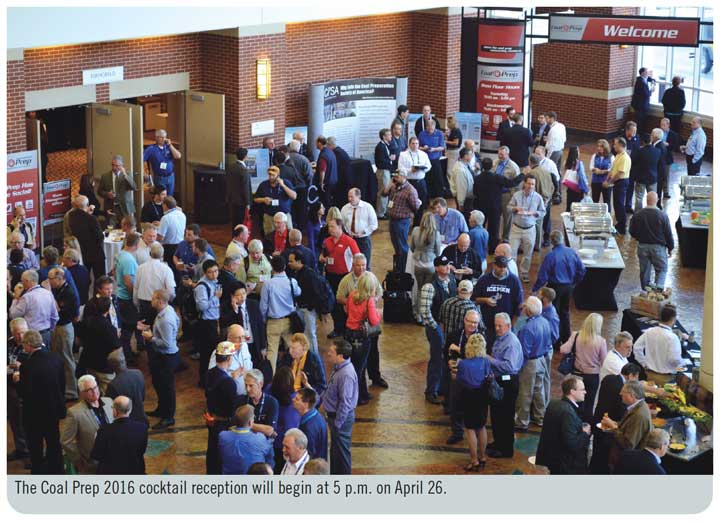

It is no surprise, then, that the Coal Prep 2016 annual exhibition and conference is moving on to a different venue for the first time in its history, leaving the long rows of post-and-board fence in Lexington for the bright lights of Louisville. Set for April 25-27 at the Louisville Exposition Center, the event is attracting a domestic and international audience from across the coal preparation and processing sectors.

According to the show director, Florence Torres, the move from the former venue of Lexington Center was a necessity for two reasons. First, the event had simply been gradually outgrowing the space; Torres said is was “bursting at the seams” in the years before the industry downturn. Second, the facility’s owners has been planning a significant renovation that forced Coal Prep officials to begin to examine alternatives a couple of years ago.

According to the show director, Florence Torres, the move from the former venue of Lexington Center was a necessity for two reasons. First, the event had simply been gradually outgrowing the space; Torres said is was “bursting at the seams” in the years before the industry downturn. Second, the facility’s owners has been planning a significant renovation that forced Coal Prep officials to begin to examine alternatives a couple of years ago.

“Louisville became an obvious option,” she said, adding that the announcement of the move and benefits was received positively — so positively that the event went ahead with the move despite the renovation funding not coming through for Lexington Center.

“Among the benefits of the move include [a] proximity to the prospering Illinois coal basin, but yet not too far away from the Appalachian roots; easier air travel for international and domestic attendees; [and] for those who drive, it may prove closer for some, yet only an hour additional drive-time for others.”

She also noted that the Kentucky Exposition Center exhibit space offers an even playing field, with contiguous hall space, and has no weight restrictions that Lexington is challenged with.

Torres noted that, as expected with ongoing market volatility, its vendor roster has scaled back; as of March 31, there were 128 exhibiting companies. Expected attendance has also declined. However, at the same time, Coal Prep still maintains a high international interest, with represented companies this year including China, Mongolia, Canada, Mexico, Cameroon, Turkey, U.K., Australia, Georgia, Norway and South Africa.

The exhibition and conference is still drawing interest from across the U.S. as well. “[The] leading states for attendees continue to be West Virginia and Kentucky,” Torres said. “As expected, Illinois attendance rose slightly given the new location in Louisville, but Pennsylvania attendance also rose compared to previous years — by 15%.”

Coal Prep officials have made a few adjustments to the agenda and overall plan for the event (see more beginning with “Coal Prep Schedule At-a-Glance”), including streamlining the workshops and technical sessions; however, in the case of the technical sessions, the topics as more buzzworthy than ever before. Again, the key word is adaptation to what’s going on in the industry, Torres said, noting that both the legislative atmosphere and the subject of rare earth elements (REEs) are hard-hitting for today’s coal community.

Coal Prep officials have made a few adjustments to the agenda and overall plan for the event (see more beginning with “Coal Prep Schedule At-a-Glance”), including streamlining the workshops and technical sessions; however, in the case of the technical sessions, the topics as more buzzworthy than ever before. Again, the key word is adaptation to what’s going on in the industry, Torres said, noting that both the legislative atmosphere and the subject of rare earth elements (REEs) are hard-hitting for today’s coal community.

“Despite the turbulent market conditions and the expected attendance reduction, we are confident that participants will benefit from the quality content and business connections that Coal Prep provides. We are looking forward to welcoming everyone in the new Louisville venue.”

Keynote Session: Steve Goreham

The distinction of being the first keynote speaker at Coal Prep’s new Louisville home goes to author and researcher Steve Goreham, MSEE/MBA, who will present “Energy, Climate Change and Public Policy” on April 26 beginning at 8:30 a.m.

Goreham, whose book titles include “The Mad, Mad, Mad World of Climatism: Mankind and Climate Change Mania,” will talk about the hold that false ideas on energy have on our society, both here and across the world, including rising pollution and resource depletion.

“[A] review of scientific data and economic trends shows that these fears are unfounded,” Goreham said. “Nevertheless, energy misconceptions provide ammunition for the current war on hydrocarbons and reasons for the misguided push for renewable alternatives. The resulting green energy policies are producing bizarre results in Europe and around the world.

“The good news is that an upheaval is coming in energy and climate regulations and industry can help accelerate this upheaval.”

The energy and environmental futurist also noted that while a majority of the U.S. Congress does not subscribe to the theory that humans are creating global warming, most of the nation’s educational institutions will not even permit a debate on the topic in a public setting.

“It’s time for industry to push back against misguided environmental ideology,” he said. The keynote is free for all badged guests.

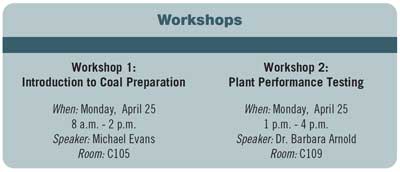

Workshops: Coal Prep Basics, Performance Testing

The two workshops being held at this year’s Coal Prep will be on April 25. Each of the very diverse topics will last a half day.

Workshop 1, “Introduction to Coal Preparation,” is returning this year after positive feedback from past attendees, and will be instructed by PrepTech President Barbara Arnold in Room C105. The longtime expert in coal froth flotation, fine particle processing, coal petrology, coal handling and blending, and more will lead a morning session beginning at 8 a.m. designed for anyone, including equipment manufacturers, utility personnel, coal purchasers, new plant hires, chemical vendors, construction personnel and support staff who are seeking to learn more about coal preparation’s foundational principles.

It will cover a large spectrum of subjects over several hours, including a review of coal properties important to coal utilization, coal sizing, cleaning and dewatering operations.

Descriptions of common coal preparation processes will be discussed, as well as sampling, handling, performance factors, and how-to-read characterization data from analyses of particle sizing and washability. Lunch is included.

In Workshop 2, “Plant Performance Testing,” presenter Michael Evans, vice president of SGS Group Management, will discuss ways to maximize a miner’s profitability through monitoring circuit efficiency. Some of the topics planned include how plant yield impacts mine profitability; the design of a testing program to maximize the value obtained; how good sampling is critical to obtaining good data; the sampling checks that must be included in the test design to ensure valid results; recordkeeping and other data that should be collected during testing; sample preparation and analysis; how to evaluate the data to maximize the test value; and how to measure efficiency and how to use results to troubleshoot an operation.

Attendees will leave the workshop with a how-to guide and also be armed with the ability to apply the principles learned at one’s own location, organizers said.

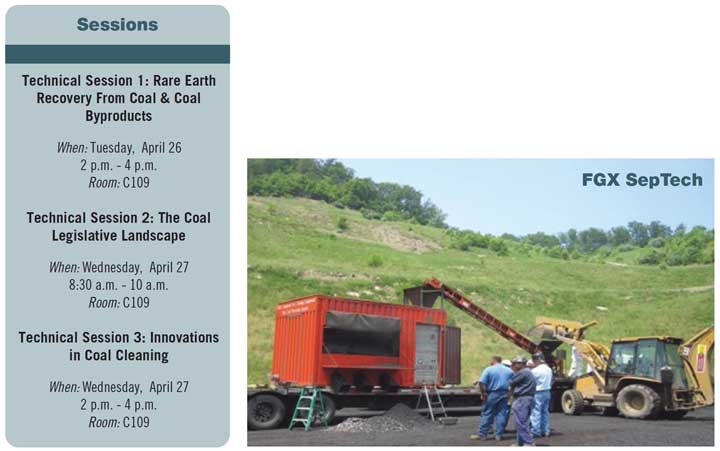

Technical Sessions Take on Legislation, Innovation

A trio of technical sessions planned for April 26 and 27 will run the topical gamut, but all have a true tie to current events and where the coal industry is heading.

The topic of REEs has been one of high interest as of late, and speakers J. Eckman, Rick Honaker, Gerald Luttrell, Gary Meenan and Aaron Noble will detail everything guests need to know at “Rare Earth Recovery From Coal and Coal Byproducts,” scheduled to begin at 2 p.m. on April 26.

Four papers will be presented in the session, including “Producing Energy Critical Elements From Coal Wastes While Reducing the Environmental Footprint of Waste Sites Associated With Coal Production and Use,” “New Opportunities: The Value of Trace Rare Earth Elements in Coal Preparation Products,” “Concentrations of REEs Generated by Eastern U.S. Coal Preparation Plants,” and “Recovery of Rare Earth Minerals and Elements From Coal and Coal Byproducts.”

With Kentucky Coal Association’s Bill Bissett, John Pippy of the Pennsylvania Coal Alliance and Steve Gardner of ECSI taking the podium, two important papers on environmental issues will be taken on in the second technical session, “The Coal Legislative Landscape,” starting at 8:30 a.m. on April 27. Paper 1, “The Clean Power Plan (CPP): An Attempt to End Coal-Fired Electricity in the United States” will examine the status of the hotly contested plan by the Obama administration as well as what’s next. In Paper 2, “The Stream Protection Rule-Potential Impacts to Coal Preparation,” Gardner will present the history and also current issues surrounding the U.S. Office of Surface Mining’s proposed new rule.

The third and final session, “Innovations in Coal Cleaning,” will be chaired by Hunter Davis and include speakers Ernst Bekker, Anthony Toney, Robert Batton, Gerald Luttrell and R.H. Yoon. The four included papers are “Optimal Utilization of Dense Medium Cyclones,” “Installation of SCI Solid Bowl Centrifuge for Recovery and Dewatering Fine Illinois Basins Coals,” “HHS Process: A New Approach for Cleaning and Dewatering Fine Illinois Basins Coals,” and “Micro-Price Optimization of Sulfer Constrained Preparation Plants with Specific Applications to Illinois Basins Coals.” It will begin at 2 p.m. on April 27 and adjourn at 4 p.m.

Spotlight on Coal Prep Exhibitors

With 129 exhibitors headed for Louisville, there is certain to be a lot happening on the show floor at this year’s Coal Prep. One of those companies is FGX SepTech.

A longtime exhibitor to the event, the Lexington-headquartered company is known for its technology as an alternative to a wet plant to upgrade coal quality and save facilities time and money. It took a significant step ahead with its offerings in February, when it announced the receipt of the latest FGX-12 plant model.

The new design has additional baghouses — instead of the dual cycle and baghouse previously used — to make for easier overall maintenance. A baghouse-only system was delivered to its Lexington warehouse recently and is the centerpiece of the company’s extensive line of plant sizes.

Additionally, FGX’s mobile prep plant has been gaining traction, with interest and use across the nation’s coalfields. Adding to that is the company’s expansion of its use for highwall mining applications in the form of its first mobile FGX-12 plant.

“FGX SepTech has continued testing a wide variety of coal from different regions in the United States and different countries,” the company said in March. “Last month, we tested coal from a large lignite mine in Texas. We also tested anthracite and graphite coal from Mexico. Some tests are conducted at our headquarters in Lexington, with others being held on the mine site with [the] mobile testing unit.”

In light of the industry’s changes, FGX SepTech has outlined several options for financing a plant, including new build/own/operate and build/own maintain options. The avenues are in addition to renting, which involves a monthly cost or per-ton fee.

In addition to the new changes to the company’s line, FGX SepTech also announced last April that it was unveiling its next-generation mobile test separator. The dry coal separator pairs a compact design (just 13-ft-3-in. × 7-ft-10-in. × 8-ft-8-in.), with a 10-raw-tons-per-hour processing capacity and easy-to-use electrical control system.

It has so far had very positive feedback to the 4-ton unit, which is capable of being trucked to sites as needed for field testing.

FGX SepTech will be exhibiting at Booth 941.

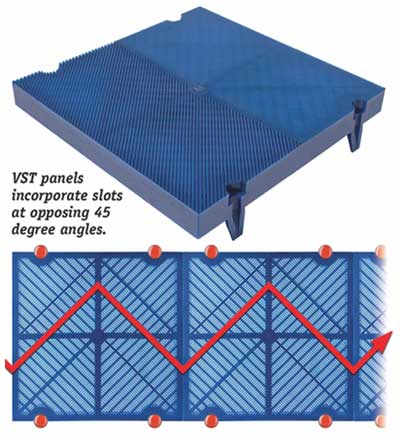

Polydeck Exhibiting at Booth 1118, Polydeck Screen will be spotlighting its Vector Slot Technology (ZST) panel and its new Metaldex product line.

Exhibiting at Booth 1118, Polydeck Screen will be spotlighting its Vector Slot Technology (ZST) panel and its new Metaldex product line.

On March 30, the South Carolina company released the new VST screen panel design, which features opposing 45˚ angles for a sig-sag flow to increase retention time and, thus, increasing draining rates per foot.

“The slots’ orientation in relation to the machine’s motion helps prevent particles from being driven into the apertures, reducing pegging and blinding problems often associated with fine sizing,” the company said, adding that the technology also provides screening/dewatering at a higher efficiency versus traditional slotted screens or continuous slot screen panels.

Polydeck said its field testing has confirmed that VST offers a lower tendency to plug, as near-sized particles provide higher open area throughout the screen panel’s life cycle.

VST is available in 0.65-mm and 1-mm apertures with more sizes coming.

Additionally, the company’s Metaldex modular screen media puts together the wear life of abrasion-resistant steel with a modular design that is easier to work with. Its pin-style fasteners are perfect with its PipeTop II stringer system, allowing the new release to be used with its Polydex or Rubberdex panel lines. There is an equal amount — or more — of open area compared to wire cloth, and with the same aperture and wire diameters.

TerraSource

TerraSource Global will be promoting coal crushing, feeding and sizing equipment from the product portfolios of its three market-leading brands.

Machinery highlighted to show visitors will include Gundlach Crusher roll crushers; Jeffrey Rader Flextooth crushers, mini hammermills and electromechanical vibrating feeders; and Pennsylvania Crusher Bradford breakers and Mountaineer II sizers.

Regional sales personnel from both their new equipment sales and parts and service business units will be on hand to answer questions and provide further information about the firm’s full range of design, build and support capabilities, which includes not only the manufacture to order new equipment, but also OEM parts, service, training, rebuilds and retrofits for equipment in the field from their three brands.

The company, which told Coal Age recently that it will not offer any demos or special events this year, but it will have staff available to answer questions, including Brian Walker, regional sales manager for crushing equipment; Mike Wiggins, regional sales manager for vibrating feeders; Rick McComas, regional sales manager for parts & service; and Arlene Willmann, marketing & event planner. TerraSource, which will be at Booth 1119, has been exhibiting at Coal Prep since the show’s inception in 1983.

Elgin

Elgin Separation Solutions will be at Coal Prep in Booth 1111, its second year at the event with its new organizational structure encompassing the familiar brands of CMI, CSI, Tabor, Norris and Clinch River.

“Elgin companies have participated in every Coal Prep since its inception,” a spokesperson said. “This year a new line of Clinch River Belt Wipers will be featured along with a completely new mechanism for the CMI line of vibratory centrifuges.”

PrepTech

In addition to Arnold’s presentation during the Coal Prep workshops on April 25, PrepTech will be appearing on the show floor in Louisville.

“Our booth will feature cyclones and spirals from Multotec, the TH Minerals filter press, SizeTec dewatering screens, CLIMAXx magnetic separators, and PrepQuip column flotation cells,” Arnold told Coal Age recently.

“This year we will also have information on Mercer International oil-water separators for clean-up around maintenance buildings/truck washes.”

At the close of the show, the company will be marking its 20th year of partnership with Coal Prep; it has been a part of the show since PrepTech’s establishment in 1997.

PrepTech will be exhibiting at Booth 1211.

Richwood

Conveyor group Richwood, which will be at Booth 916 this year, will be showing its newest product, the On-Track Return Belt Tracking Idler.

The product has been designed to prevent belt mistracking instead of constantly making adjustments to an already out-of-alignment belt.

“Most products work by constantly responding to a mistracking belt and it will go from one side to other while it continually adjusts,” spokesperson Lorrie Spence told Coal Age in early April. “The On-Track works with the natural tension of the belt to evenly distribute stresses, which keeps it in its proper path, avoiding the problem before it begins.”

Schurco Slurry

Florida-headquartered Schurco Slurry, a fixture at Coal Prep since 2004, will be returning again this year. For 2016, the company will spotlight its pump to demo its abilities to the coal preparation community.

“Given the current state of the coal market Schurco is working very closely with our distributors and customers to provide the most cost-effective pumping solutions for coal preparation plants,” spokesperson William Pierce said. “We are offering pump swaps, exchanges and remanufactured units to many customers who are looking for creative means to reduce costs.”

Schurco can be found at Booth 1028.

Force Control

Ohio-based Force Control Industries will this year be featuring its MagnaShear hazardous duty brakes at its vendor site, Booth 1432.

MagnaShear brakes employ oil shear technology to provide longer service life in demanding conveyor and crane applications. With spring set torque ratings from 3 ft-lb to 900 ft-lb available, MagnaShear brakes can be sized to the correct torque independent of the motor frame size or horsepower.

According to the company, the products meet Class I and Class II Division 2. Division 1 is in process and will be available in the near future. Also featured: a “quick-mount” capability for quick and easy mounting to drive motors in NEMA frame sizes 56 to 405.

“These proven motor brakes are totally enclosed from outside contaminants, with seal integrity for harsh and washdown environments,” the company said in March. “A modular design/assembly allows for ease of servicing and maintenance. MagnaShear [is] ideal for applications where the motor is reversed each cycle, such as cranes, winches and hoists, as well as ship and railcar loader/unloader conveyors, sweep samplers and more.”

Totally enclosed, MagnaShear brakes are also impervious to moisture, dirt and dust that is common in coal prep plants, as well as the bulk handling of coal, aggregates and more.

Company officials said the brakes are shipped ready to install, with no assembly or adjustments required, and are also available premounted on a hazardous duty motor for severe applications.

Somerset Coal

Somerset Coal

Industry newcomer Somerset Coal will be joining Coal Prep with a booth this year, its first time, that will focus on its technology for fine coal recovery, particularly the new Sub325 centrifuge system.

With a notable increase in total clean coal recovery versus traditional recovery methods — up to 5%, according to officials — that can mean substantial savings for any operation. Somerset will have a five-member team on hand to answer questions and share details on new field data from 26 different prep plants. In fact, visitors to the Somerset exhibit at Booth 1241 will be the first in the industry to see the compiled figures behind these brand new test results. The company will also have information on how a plant can add the Sub325 technology with no up-front capital — they take all the risk.

See the full Coal Prep 2016 Exhibitor List.

See the full Coal Prep 2016 Exhibitor List.